Suzuki GSX-R 1000 Service Manual: Valve guide replacement

- Remove the cylinder head. Refer to “engine top side disassembly” .

- Remove the valves. Refer to “cylinder head disassembly and assembly” .

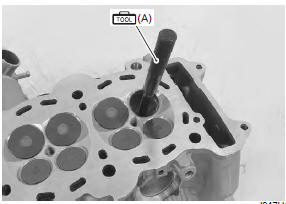

- Using the valve guide remover, drive the valve guide out toward the intake or exhaust camshaft side.

Special tool

(a): 09916–43211 (valve guide

(a): 09916–43211 (valve guide

installer &

remover)

Note

|

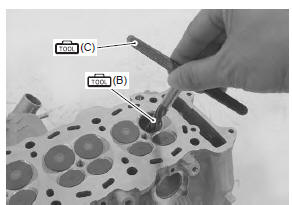

- Refinish the valve guide holes in the cylinder head using the reamer and handle.

| Caution when refinishing or removing the reamer from the valve guide hole, always turn it clockwise. |

Special tool

(b): 09916–33320 (valve guide reamer

(b): 09916–33320 (valve guide reamer

(9.8

Mm))

(c): 09916–34542 (reamer handle)

(c): 09916–34542 (reamer handle)

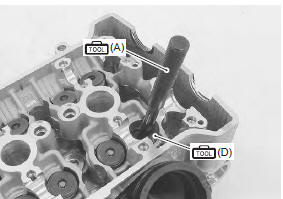

- Cool down the new valve guides in a freezer for about one hour and heat the cylinder head to 100 – 150 °c (212 – 302 °f) with a hot plate.

| Caution do not use a burner to heat the valve guide hole to prevent cylinder head distortion. |

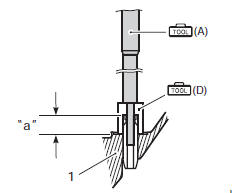

- Apply engine oil to each valve guide and valve guide hole.

- Drive the guide into the guide hole using the valve guide installer.

| Caution failure to oil the valve guide hole before driving the new guide into place may result in a damaged guide or head. |

Special tool

(a): 09916–43211 (valve guide

(a): 09916–43211 (valve guide

installer &

remover)

(d): 09916–53380 (valve guide

(d): 09916–53380 (valve guide

installer

attachment)

|

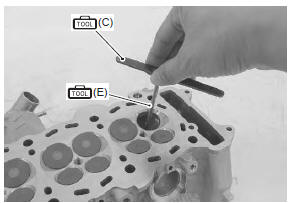

- After installing the valve guides, refinish their guiding bores using the reamer. Be sure to clean and oil the guides after reaming.

Note

|

Special tool

(c): 09916–34542 (reamer handle)

(c): 09916–34542 (reamer handle)

(e): 09916–33210 (valve guide reamer

(e): 09916–33210 (valve guide reamer

(4.5

Mm))

- Reassemble the cylinder head. Refer to “cylinder head disassembly and assembly” .

- Install the cylinder head assembly. Refer to “engine top side assembly” .

Cylinder head related parts inspection

Cylinder head related parts inspection

Refer to “cylinder head disassembly and assembly” .

Cylinder head distortion

Decarbonize the combustion chambers.

Check the gasket surface of the cylinder head for

distortion. Use a str ...

Valve seat repair

Valve seat repair

The valve seats (1) for both the intake and exhaust

valves are machined to three different angles. The seat

contact surface is cut at 45°.

Intake valve

Exhaust valve

...

Other materials:

Steering components

Steering stem head nut

Steering stem upper bracket

Steering stem lock-nut

Washer

Steering stem nut

Dust seal cover

Dust seal

Steering stem upper bearing

Steering stem lower bearing

Lower seal

Steering stem lower bracket

Steering stem lo ...

Ecm removal and installation

Removal

Remove the frame covers. Refer to “exterior parts

removal and installation” in section 9d (page 9d-

6).

Disconnect the battery (–) lead wire.

Remove the tool set (1) and prop stay (2).

Disconnect the hose clamp (3) (e-33 only) and

starter relay (4).

Remo ...

Rear brake caliper parts inspection

Refer to “rear brake caliper disassembly and assembly” .

Brake caliper cylinder

Inspect the brake caliper cylinder wall for nicks,

scratches or other damage. If any damage is found,

replace the caliper with a new one.

Brake caliper piston

Inspect the brake caliper piston surface for any

s ...