Suzuki GSX-R 1000 Service Manual: Cylinder head cover disassembly and assembly

Disassembly

- Remove the cylinder head cover. Refer to “engine top side disassembly” .

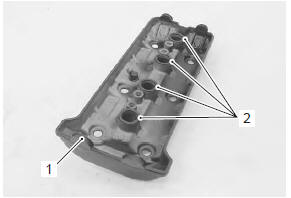

- Remove the gaskets (1) and (2).

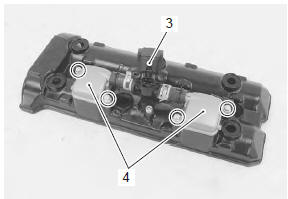

- Remove the pair control solenoid valve (3) along with the pair reed valve covers (4).

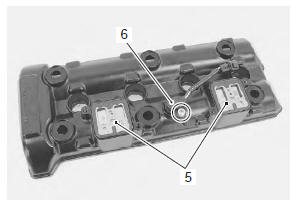

- Remove the pair reed valves (5) and cmp sensor (6).

Assembly

Assembly is in the reverse order of disassembly. Pay attention to the following points:

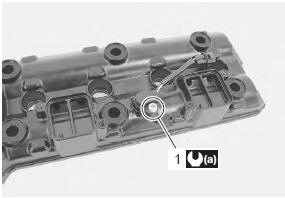

- install the cmp sensor.

| Note when installing the cmp sensor, clean the sensor surface. |

- Tighten the cmp sensor bolt (1) to the specified torque.

Tightening torque cmp sensor bolt (a): 10 n·m (1.0 Kgf-m, 7.0 Lbf-ft)

- Install the pair reed valves.

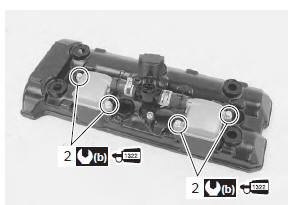

- Apply thread lock to the pair reed valve cover bolts (2) and tighten them to the specified torque.

: Thread lock cement

: Thread lock cement

99000–32110

(thread lock cement super “1322” or

equivalent)

Tightening torque pair reed valve cover bolt (b): 10 n·m (1.0 Kgf-m, 7.0 Lbf-ft)

- Fit new gaskets and install the cylinder head cover to the cylinder head. Refer to “engine top side assembly” .

Engine top side assembly

Engine top side assembly

Assemble the engine top side in the reverse order of

disassembly. Pay attention to the following points:

Cylinder head

Install the dowel pins and a new cylinder head gasket

(1) to the cylinder ...

Cylinder head cover related parts

inspection

Cylinder head cover related parts

inspection

Refer to “engine top side disassembly” .

Refer to “engine top side assembly” .

Refer to “cylinder head cover disassembly and assembly” .

Cylinder head cover

Clean and check the gasket grooves ...

Other materials:

Engine coolant

Coolant level

The engine coolant solution

should be between "f" (full) and

"1..:' (Low) level lines on the engine

coolant reservoir. If the level is

lower than "1..:' (Low) level line,

bring it up to "f" (full) level by adding

50:50 mixture of distilled water ...

Clutch components

Clutch pressure plate

Clutch push piece

No. 1 Drive plate (8 pcs.)

No. 3 Driven plate (0 – 2 pcs.)

No. 1 Driven plate (5 – 7 pcs.)

No. 2 Driven plate (1 pc.)

No. 2 Drive plate (1 pc.)

Spring washer

Spring washer seat

Clutch sleeve hub

Seat ...

Specifications

Tightening torque specifications

Note

the specified tightening torque is described in the following.

“Body frame construction” “front footrest bracket construction”

“side-stand construction”

Reference: for the tightening torque of fastener not specified in this ...