Suzuki GSX-R 1000 Service Manual: Balancer shaft journal bearing inspection and selection

Refer to “engine bottom side disassembly” (page 1d- 49).

Refer to “engine bottom side assembly” .

Inspection

Inspect the bearing surfaces for any signs of fusion, pitting, burn or flaws. If any, replace them with a specified set of bearings.

Selection

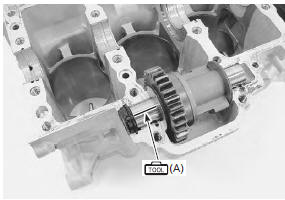

- Place the plastigauge axially along the balancer shaft journal as shown.

Special tool (a): 09900–22301 (plastigage (0.025 – 0.076 Mm))

| Caution never rotate the balancer shaft when a piece of plastigauge is installed. |

- Mate the lower crankcase with the upper crankcase, and tighten the crankcase bolts (m8) and crankshaft journal bolts (m9) to the specified torque.

Tightening torque crankshaft journal bolt (m9): 18 n·m (1.8 Kgf-m, 13.0 Lbf-ft) then turn in 50° crankcase bolt (m8) (initial): 15 n·m (1.5 Kgf-m, 11.0 Lbf-ft) crankcase bolt (m8) (final): 26 n·m (2.6 Kgf-m, 19.0 Lbf-ft) crankcase bolt (m6): 12 n·m (1.2 Kgf-m, 8.5 Lbfft)

- Remove the lower crankcase and measure the width of the compressed plastigauge using the envelope scale. This measurement should be taken at the widest part of the compressed plastigauge. If the oil clearance exceeds the service limit, select the specified bearings from the bearing selection table.

Balancer shaft journal oil clearance standard: 0.028 – 0.052 Mm (0.0011 – 0.0020 In) service limit: 0.080 Mm (0.0031 In)

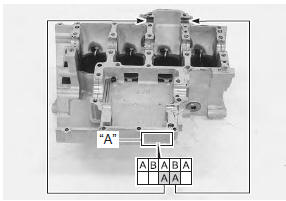

- Check the corresponding crankcase journal i.D.

Code number “a”, [a], [b] or [c] which is stamped on the rear of upper crankcase.

Bearing selection table

Crankcase I.D. Specification

Balancer shaft journal o.D. Specification 19.992 – 20.000 Mm (0.7871 – 0.7874 In)

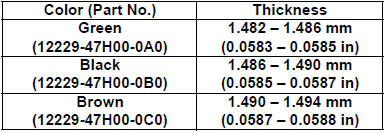

Bearing thickness specification

| Note the balancer shaft journal bearings on upper and lower crankcases are the same. |

Balancer shaft journal bearing removal and

installation

Balancer shaft journal bearing removal and

installation

Refer to “engine bottom side disassembly” (page 1d-

49).

Refer to “engine bottom side assembly” .

Removal

Remove the balancer shaft journal bearings (1).

Note

do not remove the ...

Conrod crank pin bearing removal and

installation

Conrod crank pin bearing removal and

installation

Refer to “engine bottom side disassembly” (page 1d-

49).

Refer to “engine bottom side assembly” .

Removal

Remove the conrod crank pin bearings (1).

Note

do not remove the beari ...

Other materials:

Sds check

Using sds, sample the data at the time of new and periodic vehicle

inspections.

After saving the sampled data in the computer, file them by model and by user.

The periodically filed data help improve the accuracy of troubleshooting since

they can indicate the condition of vehicle

function ...

Know your limits

Always ride within the boundaries

of your own skills. Knowing these

limits and staying within them will

help you avoid accidents.

A major cause of accidents involving

only a motorcycle (and no

cars) is going too fast through a

turn. Before entering a turn, select

an appropriately low corne ...

Cooling fan inspection

Cooling fan operating temperature

standard

(on → off): approx. 100 ?‹C (212 ƒ‹f)

(off → on): approx. 105 ?‹C (221 ƒ‹f)

Inspect the cooling fan in the following procedures:

disconnect the cooling fan motor coupler (1).

Test the cooling fan motor for load ...