Suzuki GSX-R 1000 Service Manual: Crankshaft thrust clearance inspection and selection

Refer to “engine bottom side disassembly” (page 1d- 49).

Refer to “engine bottom side assembly” .

Inspection

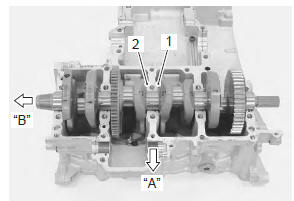

- With the crankshaft’s right-side and left-side thrust bearings inserted into the upper crankcase.

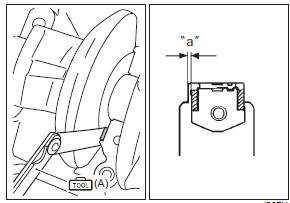

- Measure the thrust clearance “a” between the leftside thrust bearing and crankshaft using the thickness gauge. If the thrust clearance exceeds the standard range, adjust the thrust clearance.

| Note pull the crankshaft to the left (generator side) so that there is no clearance on the right-side thrust bearing. |

Special tool

: 09900–20803 (thickness gauge)

: 09900–20803 (thickness gauge)

Crankshaft thrust clearance “a” standard: 0.060 – 0.110 Mm (0.0024 – 0.0043 In)

|

Selection

- Remove the right-side thrust bearing and measure its thickness using the micrometer. If the thickness of the right-side thrust bearing is below standard, replace it with a new bearing and measure the thrust clearance again, as described in inspection 1) and 2).

Special tool

(a): 09900–20205 (micrometer (0 – 25

(a): 09900–20205 (micrometer (0 – 25

mm))

Right-side thrust bearing thickness standard: 2.420 – 2.440 Mm (0.0953 – 0.0961 In)

- If the right-side thrust bearing is within the standard range, reinsert the right-side thrust bearing and remove the left-side thrust bearing.

- With the left-side thrust bearing removed, measure the clearance “a” using the thickness gauge as shown.

Special tool

(b): 09900–20803 (thickness gauge)

(b): 09900–20803 (thickness gauge)

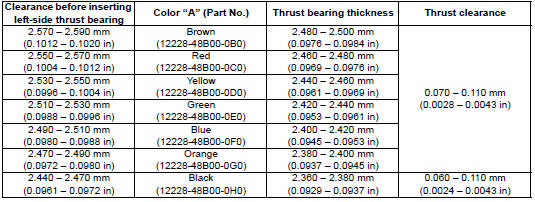

- Select a left-side thrust bearing from the selection table.

| Note right-side thrust bearing has the same specification as the green (12228-48b00-0e0) of left-side thrust bearing. |

Thrust bearing selection table

|

- After selecting a left-side thrust bearing, install it and then measure the thrust clearance again.

Crankshaft journal bearing inspection and

selection

Crankshaft journal bearing inspection and

selection

Refer to “engine bottom side disassembly” (page 1d-

49).

Refer to “engine bottom side assembly” .

Inspection

Inspect each upper and lower crankcase bearing for

any damage.

Set ...

Specifications

Specifications

...

Other materials:

Balancer shaft disassembly and assembly

Refer to “engine bottom side disassembly” (page 1d-

49).

Refer to “engine bottom side assembly” .

Disassembly

Remove the balancer shaft. Refer to “engine bottom side disassembly” .

Remove the washers, balancer gear and dampers

from the shaft.

Assembly

Assembly is in the re ...

Rear suspension components

Rear shock absorber

Rear shock absorber mounting nut

Cushion rod

Cushion rod mounting nut

Cushion lever

Cushion lever mounting nut

Swingarm pivot lock-nut

Swingarm pivot shaft

Swingarm pivot nut

Swingarm

Chain case

Plate

Chain adjus ...

Special tools and equipment

Recommended service material

Note

required service material is also described in the following.

“Front brake components”

Special tool

...