Suzuki GSX-R 1000 Service Manual: Cylinder head disassembly and assembly

Refer to “engine top side disassembly” .

Refer to “engine top side assembly” .

| Caution identify the position of each removed part. Organize the parts in their respective groups (i.E., Intake, exhaust, no. 1 Or no. 2) So that they can be installed in their original locations. |

Disassembly

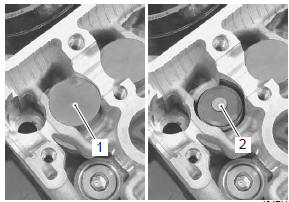

- Remove the tappet (1) and shim (2) by fingers or magnetic hand.

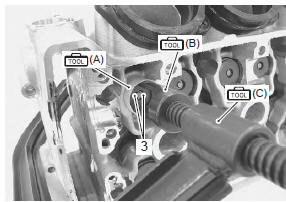

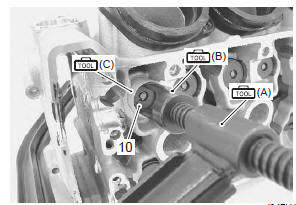

- Insert the special tool (a) between the valve springs and cylinder head.

- Using the special tools, compress the valve springs and remove the two cotter halves (3) from the valve stem.

| Caution be careful not to damage the tappet sliding surface with the special tool. |

Special tool

(a): 09919–28620 (sleeve protector)

(a): 09919–28620 (sleeve protector)

(b): 09916–14522 (valve lifter

(b): 09916–14522 (valve lifter

attachment)

(c): 09916–14510 (valve lifter)

(c): 09916–14510 (valve lifter)

: 09916–84511 (tweezer)

: 09916–84511 (tweezer)

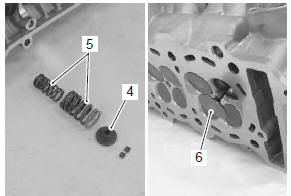

- Remove the valve spring retainer (4) and valve springs (5).

- Pull out the valve (6) from the combustion chamber side.

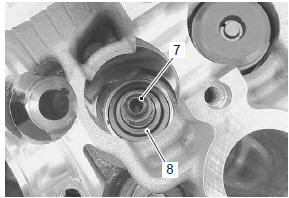

- Remove the oil seal (7) and spring seat (8).

- Remove the other valves in the same manner as described previously.

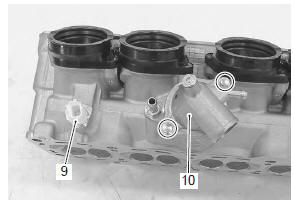

- Remove the ect sensor (9).

- Remove the thermostat cover (10).

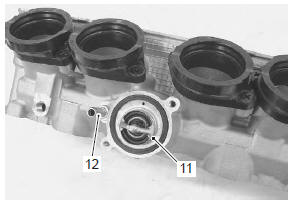

- Remove the thermostat (11).

- Remove the bypass hose union (12).

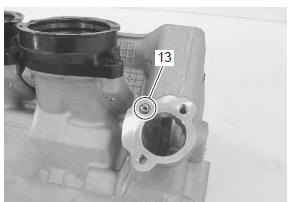

- Remove the oil jet (13).

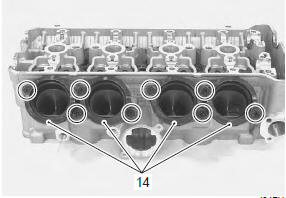

- Remove the intake pipes (14).

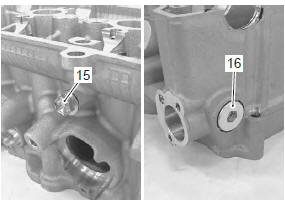

- Remove the oil gallery plug (15).

- Remove the cam chain tension adjuster service cap (16).

Assembly

Assembly is in the reverse order of disassembly. Pay attention to the following points:

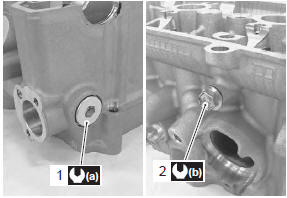

- tighten the cam chain tension adjuster service cap (1) and oil gallery plug (2) to the specified torque.

| Caution replace the gaskets with new ones. |

Tightening torque cam chain tension adjuster service cap (a): 23 n·m (2.3 Kgf-m, 16.5 Lbf-ft) oil gallery plug (cylinder head) (b): 10 n·m (1.0 Kgf-m, 7.0 Lbf-ft)

- Apply grease to o-rings of the intake pipes.

| Caution replace the o-rings with new ones. |

: Grease 99000–25010 (suzuki

: Grease 99000–25010 (suzuki

super

grease “a” or equivalent)

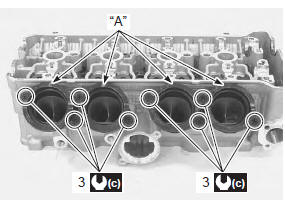

- Install the intake pipes with the up mark “a” facing top side.

- Tighten the intake pipe bolts (3) to the specified torque.

Tightening torque intake pipe bolt (c): 8.5 N·m (0.85 Kgf-m, 6.5 Lbf-ft)

- Apply engine oil to the o-ring and install the oil jet.

| Caution use new o-ring to prevent oil pressure leakage |

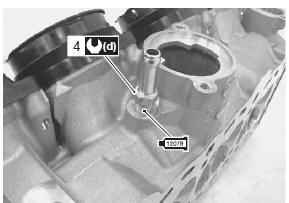

- Apply bond to the thread part of bypass hose union (4) and tighten it to the specified torque.

: Sealant 99000–31140 (suzuki

: Sealant 99000–31140 (suzuki

bond

no.1207B or equivalent)

Tightening torque bypass hose union (d): 12 n·m (1.2 Kgf-m, 8.5 Lbfft)

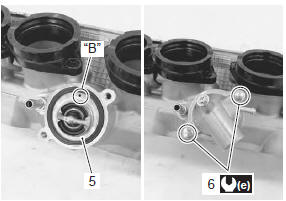

- Install the thermostat (5)

| Note the air bleeder hole “b” of the thermostat faces upside. |

- Tighten the thermostat cover bolts (6) to the specified torque.

Tightening torque thermostat cover bolt (e): 10 n·m (1.0 Kgf-m, 7.0 Lbf-ft)

- Tighten the ect sensor (7) to the specified torque.

Tightening torque ect sensor (f): 18 n·m (1.8 Kgf-m, 13.0 Lbf-ft)

Caution

|

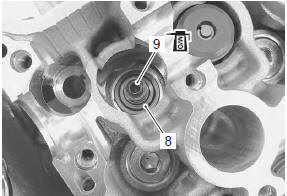

- Install the valve spring seat (8).

- Apply molybdenum oil to the oil seal (9), and press-fit it into the position.

| Caution do not reuse the removed oil seal. |

M/o: molybdenum oil (molybdenum oil solution)

- Insert the valve, with its stem coated with molybdenum oil solution all around and along the full stem length without any break.

| Caution when inserting the valve, take care not to damage the lip of the oil seal. |

M/o: molybdenum oil (molybdenum oil solution)

- Install each valve spring with the small-pitch portion “c” facing cylinder head.

|

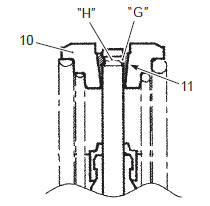

- Put on the valve spring retainer (10), and using the special tools, press down the springs, fit the cotter halves to the stem end, and release the lifter to allow the cotter halves to wedge in between retainer and stem.

Caution

|

Special tool

(a): 09916–14510 (valve lifter)

(a): 09916–14510 (valve lifter)

(b): 09916–14522 (valve lifter

(b): 09916–14522 (valve lifter

attachment)

(c): 09919–28620 (sleeve protector)

(c): 09919–28620 (sleeve protector)

: 09916–84511 (tweezer)

: 09916–84511 (tweezer)

- Be sure that the rounded lip “g” of the cotter fits snugly into the groove “h” in the stem end.

|

- Install the other valves and springs in the same manner as described previously.

- Install the tappet shims and the tappets to their original positions.

Note

|

Cam chain tensioner inspection

Cam chain tensioner inspection

Inspect the cam chain tensioner in the following

procedures:

remove the cam chain tensioner. Refer to “cam chain guide / cam chain

tensioner removal and installation” .

Check the ...

Cylinder head related parts inspection

Cylinder head related parts inspection

Refer to “cylinder head disassembly and assembly” .

Cylinder head distortion

Decarbonize the combustion chambers.

Check the gasket surface of the cylinder head for

distortion. Use a str ...

Other materials:

Brake fluid

Check the brake fluid level in both front and rear brake fluid reservoirs. If

the level in either reservoir is below the lower mark, inspect for brake pad

wear and leaks.

Warning

Brake fluid is harmful or fatal if

swallowed, and harmful if it

comes in contact with skin or

...

DTC “c22” (p1450-h/l): ap sensor circuit

malfunction

Detected condition and possible cause

Detected condition

Possible cause

C22

Ap sensor voltage is not within the

following range.

0.5 V ≤ Sensor voltage < 4.85 V

Note

note that atmospheric pressure

varies depending on weather

co ...

Rear suspension components

Rear shock absorber

Rear shock absorber mounting nut

Cushion rod

Cushion rod mounting nut

Cushion lever

Cushion lever mounting nut

Swingarm pivot lock-nut

Swingarm pivot shaft

Swingarm pivot nut

Swingarm

Chain case

Plate

Chain adjus ...