Suzuki GSX-R 1000 Service Manual: Engine assembly installation

Install the engine in the reverse order of engine removal.

Pay attention to the following points:

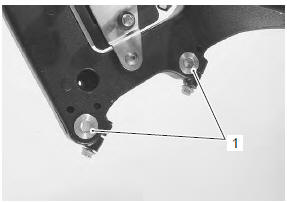

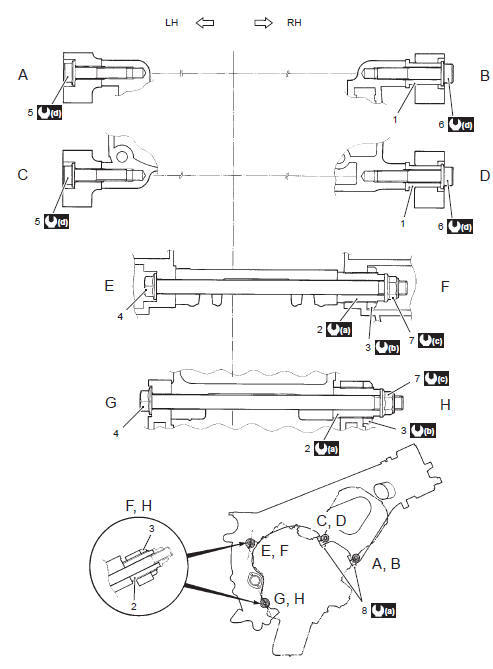

- before installing the engine, install the collars (1).

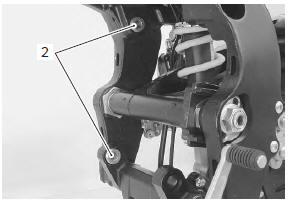

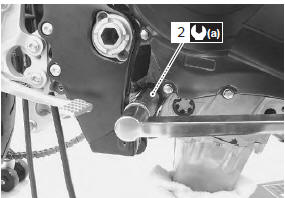

- Before installing the engine, install the engine mounting thrust adjusters (2).

- Gradually raise the rear side of the engine assembly, and then put the drive chain on the driveshaft.

| Caution be careful not to catch the wiring harness between the frame and the engine. |

- Install all engine mounting bolts and tighten them temporarily.

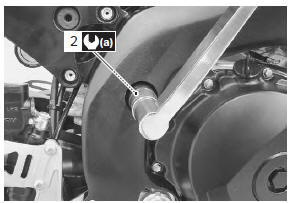

- Tighten the engine mounting thrust adjusters (2) to the specified torque.

Tightening torque engine mounting thrust adjuster (a): 23 n·m (2.3 Kgf-m, 16.5 Lbf-ft)

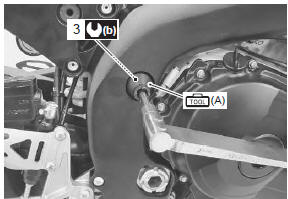

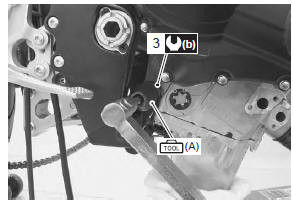

- Tighten the engine mounting thrust adjuster lock-nuts (3) to the specified torque with the special tool.

Tightening torque engine mounting thrust adjuster lock-nut (b): 45 n·m (4.5 Kgf-m, 32.5 Lbf-ft)

Special tool

(a): 09940–14990 (engine mounting

(a): 09940–14990 (engine mounting

adjust

wrench)

- Tighten all engine mounting bolts and nuts to the specified torque, as shown in the following illustration

| Note the engine mounting nuts are self-locking. Once the nuts have been removed, they are no longer of any use. |

- Tighten the engine mounting pinch bolt to the specified torque, as shown in the following illustration.

|

- Install the engine sprocket. Refer to “engine sprocket removal and installation” in section 3a .

- Install the exhaust pipe assembly and muffler. Refer to “muffler / muffler chamber / exhaust pipe removal and installation” in section 1k .

- Install the radiator. Refer to “radiator / cooling fan motor removal and installation” in section 1f .

- Install the throttle body. Refer to “throttle body removal and installation” .

- Install the air cleaner box. Refer to “air cleaner box removal and installation” .

- After remounting the engine, route the wiring harness, cable and hoses properly. Refer to “wiring harness routing diagram” in section 9a , “throttle cable routing diagram” and “water hose routing diagram” in section 1f .

- Pour engine coolant and engine oil. Refer to “cooling system inspection” in section 0b and “engine oil and filter replacement” in section 0b .

- After finishing the engine installation, check the following items.

- Throttle cable play refer to “throttle cable play inspection and adjustment” in section 0b .

- Throttle valve synchronization refer to “throttle valve synchronization” (page 1d- 16).

- Clutch cable play refer to “clutch cable play inspection and adjustment” in section 0b .

- Drive chain slack refer to “drive chain inspection and adjustment” in section 0b .

- Engine oil and coolant leakage refer to “cooling circuit inspection” in section 1f .

Engine assembly removal

Engine assembly removal

Before taking the engine out of the frame, wash the

engine using a steam cleaner. Engine removal is

sequentially explained in the following steps:

remove the side cowlings. Refer to “exter ...

Engine top side disassembly

Engine top side disassembly

It is unnecessary to remove the engine assembly from

the frame when servicing the cylinder head cover and

camshafts.

Note

before servicing the engine top side

components (until camshaf ...

Other materials:

DTC “c40” (p0505 / p0506 / p0507): isc

valve circuit malfunction

Detected condition and possible cause

Detected condition

Possible cause

C40/P0505

The circuit voltage of motor drive is

unusual.

Isc valve circuit open or shorted to ground.

Air passage clogged.

Isc valve is fixed.

Isc valve prese ...

Engine coolant recommendation

Engine coolant

Use an anti-freeze/engine coolant compatible with an

aluminum radiator, mixed with distilled water only.

Water for mixing

Use distilled water only. Water other than distilled water

can corrode and clog the aluminum radiator.

Anti-freeze / engine coolant

The engine coolant perfo ...

Rear suspension components

Rear shock absorber

Rear shock absorber mounting nut

Cushion rod

Cushion rod mounting nut

Cushion lever

Cushion lever mounting nut

Swingarm pivot lock-nut

Swingarm pivot shaft

Swingarm pivot nut

Swingarm

Chain case

Plate

Chain adjus ...

23

23

45 N·m (4.5

45 N·m (4.5

75 N·m (7.5

75 N·m (7.5

55 N·m (5.5

55 N·m (5.5