Suzuki GSX-R 1000 Service Manual: Engine assembly removal

Before taking the engine out of the frame, wash the engine using a steam cleaner. Engine removal is sequentially explained in the following steps:

- remove the side cowlings. Refer to “exterior parts removal and installation” in section 9d (page 9d- 6).

- Remove the front seat. Refer to “exterior parts removal and installation” in section 9d (page 9d- 6).

- Disconnect the battery (–) lead wire (1).

- Jack up the motorcycle and fix it for safety.

- Drain engine oil. Refer to “engine oil and filter replacement” in section 0b .

- Drain engine coolant. Refer to “engine oil and filter replacement” in section 0b .

- Lift and support the fuel tank. Refer to “fuel tank removal and installation” in section 1g (page 1g- 9).

- Remove the air cleaner box. Refer to “air cleaner box removal and installation” .

- Remove the throttle body assembly. Refer to “throttle body removal and installation” (page 1d- 10).

- Remove the oil cooler and hoses. Refer to “oil cooler / oil cooler hose removal and installation” in section 1e .

- Remove the radiator assembly. Refer to “radiator / cooling fan motor removal and installation” in section 1f .

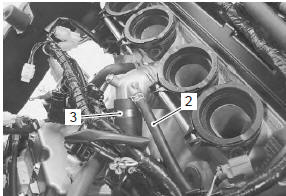

- Disconnect the water/air bleed hose (2) and radiator inlet hose (3).

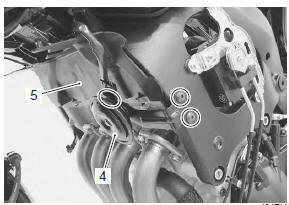

- Remove the horn (4) and radiator heat guard (5).

- Remove the radiator/oil cooler mounting bracket (6).

- Remove the exhaust system components. Refer to “muffler / muffler chamber / exhaust pipe removal and installation” in section 1k .

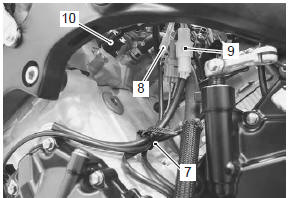

- Remove the clamp (7).

- Disconnect the oil pressure switch lead wire coupler (8), generator lead wire coupler (9) and ect sensor coupler (10).

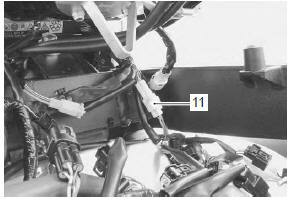

- Disconnect the gp switch lead wire coupler (11).

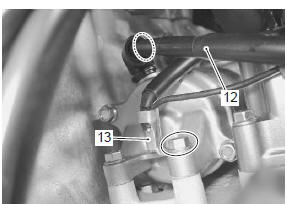

- Disconnect the starter motor lead wire (12) and engine ground lead wire (13).

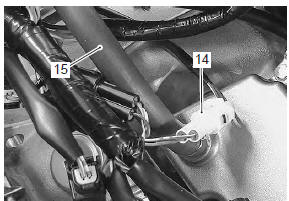

- Disconnect the ckp sensor lead wire coupler (14).

- Remove the crankcase breather (pcv) hose (15).

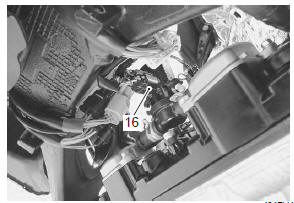

- Disconnect the pair solenoid valve coupler (16).

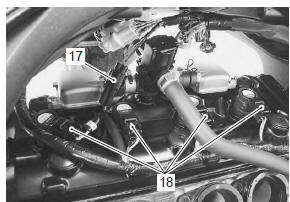

- Disconnect the cmp sensor lead wire coupler (17) and ignition coil couplers (18).

- Remove the ignition coils.

Caution

|

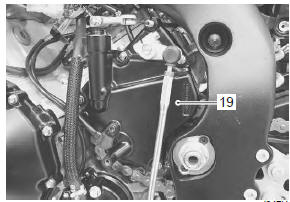

- Remove the engine sprocket cover (19). Refer to “engine sprocket removal and installation” in section 3a .

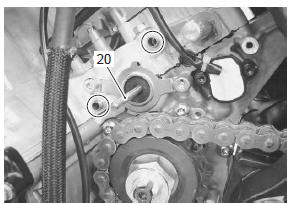

- Remove the dowel pins and clutch push rod (20).

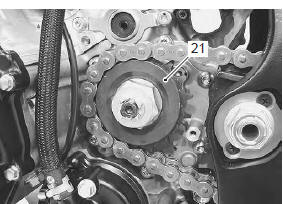

- Remove the engine sprocket (21). Refer to “engine sprocket removal and installation” in section 3a .

- Support the engine using an engine jack.

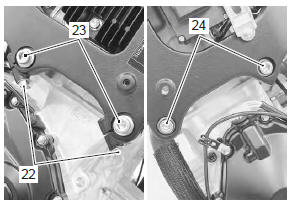

- Loosen the engine mounting pinch bolts (22) (rh).

- Remove the engine mounting bolts (23) (rh).

- Remove the engine mounting bolts (24) (lh).

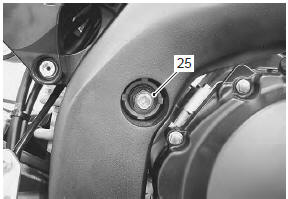

- Remove the engine mounting nut (25).

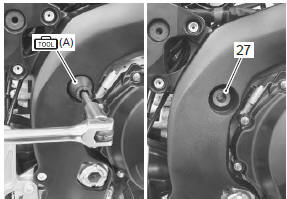

- Remove the engine mounting thrust adjuster locknut (26) with the special tool.

- Loosen the engine mounting thrust adjuster (27) fully.

Special tool

(a): 09940–14990 (engine mounting

(a): 09940–14990 (engine mounting

adjust

wrench)

| Note do not remove the engine mounting bolt at this stage. |

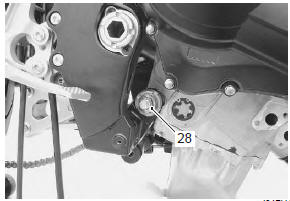

- Remove the engine mounting nut (28).

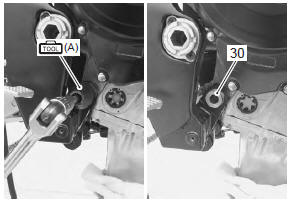

- Loosen the engine mounting thrust adjuster lock-nut (29) with the special tool.

- Loosen the engine mounting thrust adjuster (30) fully.

Special tool

(a): 09940–14990 (engine mounting

(a): 09940–14990 (engine mounting

adjust

wrench)

| Note do not remove the engine mounting bolt at this stage. |

- Remove the engine mounting bolts and gradually lower the front side of the engine. Then, take off the drive chain from the driveshaft.

- Remove the engine assembly.

Tp reset

Tp reset

When replacing the throttle body assembly or tp sensor

with a new one or reinstalling the tp sensor, reset the

tp learned value in the following procedures:

Note

keep the throttle valves ...

Engine assembly installation

Engine assembly installation

Install the engine in the reverse order of engine removal.

Pay attention to the following points:

before installing the engine, install the collars (1).

Before installing the en ...

Other materials:

Rear shock absorber removal and installation

Removal

Remove the right side cowling and side frame covers. Refer to “exterior

parts removal and installation” in section 9d .

Support the motorcycle with a jack to relieve load on

the rear shock absorber.

Remove the left muffler and muffler chamber heat guard no. 2. Refer ...

Special tools and equipment

Recommended service material

Note

required service material is also described in the following.

“Handlebar components” “steering components” “steering

damper construction”

Special tool

...

Water hose inspection

Inspect the water hoses in the following procedures:

remove the side cowlings. Refer to “exterior parts

removal and installation” in section 9d (page 9d-

6).

Check the water hoses for crack, damage or engine

coolant leakage. If any defect is found, replace the

water hose wi ...