Suzuki GSX-R 1000 Service Manual: Fi system troubleshooting

Customer complaint analysis

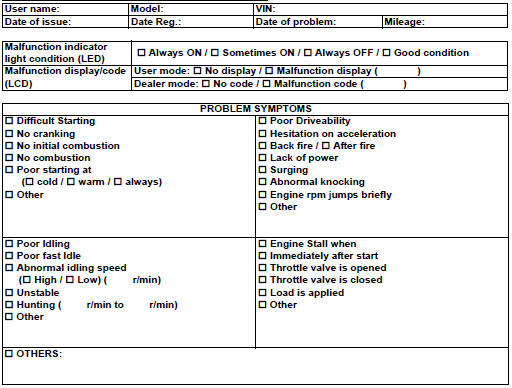

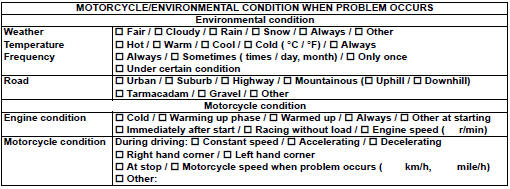

Record details of the problem (failure, complaint) and how it occurred as described by the customer. For this purpose, use of such an inspection form such as following will facilitate collecting information to the point required for proper analysis and diagnosis.

| Note this form is a standard sample. The form should be modified according to conditions and characteristic of each market. |

Example: customer problem inspection form

Visual inspection

Prior to diagnosis using the mode select switch or sds, perform the following visual inspections. The reason for visual inspection is that mechanical failures (such as oil leakage) cannot be displayed on the screen with the use of mode select switch or sds.

- Engine oil level and leakage. Refer to “engine oil and filter replacement” in section 0b .

- Engine coolant level and leakage. Refer to “cooling circuit inspection” in section 1f .

- Fuel level and leakage. Refer to “fuel line inspection” in section 0b .

- Clogged air cleaner element. Refer to “air cleaner element inspection” in section 0b .

- Battery condition.

- Throttle cable play. Refer to “throttle cable play inspection and adjustment” in section 0b .

- Vacuum hose looseness, bend and disconnection.

- Broken fuse.

- Fi indicator light operation. Refer to “combination meter inspection” in section 9c .

- Each warning indicator light operation. Refer to “combination meter inspection” in section 9c .

- Speedometer operation. Refer to “speedometer inspection” in section 9c .

- Exhaust gas leakage and noise. Refer to “exhaust system inspection” in section 1k .

- Each coupler disconnection.

- Clogged radiator fins. Refer to “radiator inspection and cleaning” in section 1f

Fail-safe function table

Fail-safe function table

Fi system is provided with fail-safe function to allow the engine to start

and the motorcycle to run in a minimum

performance necessary even under malfunction condition.

The engine can sta ...

Malfunction code and defective condition table

Malfunction code and defective condition table

* : Immobilizer system equipped model only. ...

Other materials:

Fastener removal and installation

Type a

Removal

Depress the head of fastener center piece (1).

Pull out the fastener (2).

Installation

Let the center piece stick out toward the head so that

the pawls “a” closes.

Insert the fastener into the installation hole.

Note

to prevent the pawl ...

Oil cooler / oil cooler hose inspection and

cleaning

Refer to “exterior parts removal and installation” in section 9d .

Oil cooler hose inspection

Inspect the oil cooler hoses for any damage and oil

leakage. If any defects are found, replace the oil cooler

hose with a new one.

Oil cooler inspection

Remove the oil cooler guard (1).

...

Regulator / rectifier construction

Regulator/rectifier

Regulator/rectifier bracket

Air intake pipe (rh)

Spacer

Wiring harness

Connect

the regulator/rectifier couplers under the wiring harness

10

N·m (1.0 Kgf-m, 7.0 Lbf-ft)

...