Suzuki GSX-R 1000 Service Manual: Front fork parts inspection

Refer to “front fork disassembly and assembly” .

Inner and outer tubes

Inspect the inner tube and outer tube for scratches

Slide bushing / guide bushing

Inspect the slide bushing and guide bushing for wear or damage. If they are worn or damaged, replace them with new ones. If they are not clean, clean them with a nylon brush and fork oil.

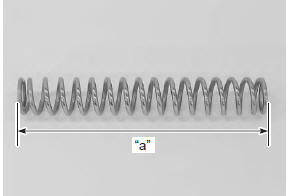

Fork spring

Measure the fork spring free length “a”. If it is shorter than the service limit, replace it with a new one.

Front fork spring free length “a” service limit: 236 mm (9.29 In)

Piston rod / piston ring

Inspect the piston rod and piston ring (1) for wear or damage. If any defects are found, replace the piston rod with a new one

Front fork disassembly and assembly

Front fork disassembly and assembly

Refer to “front fork removal and installation” (page 2b-

2).

Note

the right and left front forks are installed

symmetrically and therefore the disassembly

procedure for one side is t ...

Rod guide case tightening torque

Rod guide case tightening torque

Tighten the rod guide case in the following procedures:

measure the effective length l of the torque wrench.

Calculate the reading torque on the torque wrench by

use of the formula shown below.

...

Other materials:

Ignition coil and spark plug removal and

installation

Removal

The hot

engine can burn you.

Wait until the engine is cool enough to touch.

Turn the ignition switch off.

Remove the air cleaner box. Refer to “air cleaner box removal and

installation” in section 1d .

Disconnect the lead wire couplers (1).

...

Rear brake caliper removal and installation

Removal

Remove the rear wheel. Refer to “rear wheel assembly removal and

installation” in section 2d .

Drain brake fluid. Refer to “brake fluid replacement” in section 4a .

Remove the brake hose from the caliper by

removing the union bolt (1) and catch the brake fluid

in a ...