Suzuki GSX-R 1000 Service Manual: Front fork disassembly and assembly

Refer to “front fork removal and installation” (page 2b- 2).

| Note the right and left front forks are installed symmetrically and therefore the disassembly procedure for one side is the same as that for the other side. |

Disassembly

- Turn the spring pre-load adjuster (1) to the softest position.

- Loosen the front fork cap using the special tool and vise.

| Caution do not clamp the outer tube too tight. |

Special tool (a): 09941–53670 (front fork cap socket wrench (45 mm))

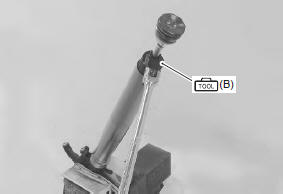

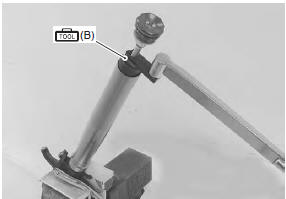

- Loosen the rod guide case installed in the inner tube using the special tool.

Special tool

(b): 09940–84710 (rod guide case

(b): 09940–84710 (rod guide case

wrench)

Hold the Hold the

front fork cap when removing the rod guide case, or it will jump out due to the spring pressure. |

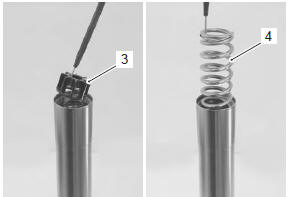

- Remove the piston rod assembly (2).

- Remove the spring collar b (3) and spring (4).

- Drain fork oil and remove the spring collar a (5).

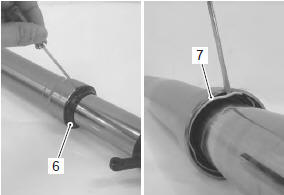

- Remove the dust seal (6).

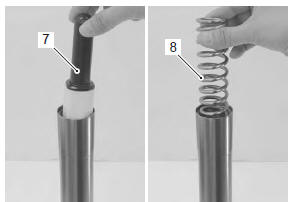

- Remove the oil seal stopper ring (7).

Caution

|

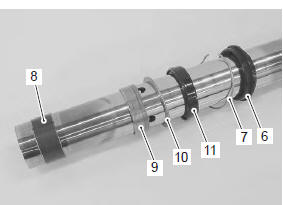

- Pull out the inner tube from the outer tube.

- Remove the slide bushing (8) from the inner tube.

- Remove the following parts from the inner tube.

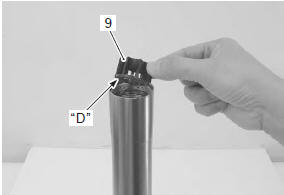

- guide bushing (9)

- oil seal spacer (10)

- oil seal (11)

- oil seal stopper ring (7)

- dust seal (6)

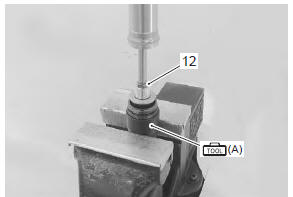

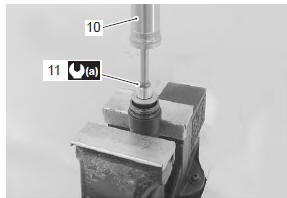

- Hold the piston rod assembly with the special tool and vise.

Special tool

(a): 09941–53670 (front fork cap

(a): 09941–53670 (front fork cap

socket

wrench (45 mm))

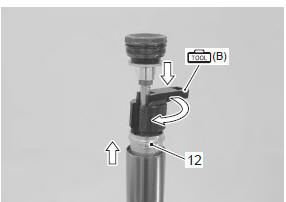

- Loosen the piston rod nut (12) and disassemble the piston rod as shown.

Assembly

Caution

|

- Cover the inner tube with a plastic film.

- Install the following parts to the inner tube.

- new dust seal (1)

- stopper ring (2)

- new oil seal (3)

Caution

|

|

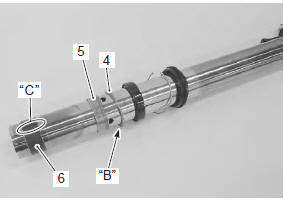

- Remove the plastic film and install the oil seal spacer (4), guide bushing (5) and slide bushing (6) keep them free from dust.

Caution

|

|

- Insert the inner tube into the outer tube.

- Press fit the guide bushing (5) using the special tools.

- Press fit the new oil seal (3) using the special tools until the stopper ring groove on the outer tube can be seen.

Special tool

(a): 09940–52861 (front fork oil

(a): 09940–52861 (front fork oil

seal

installer set)

- Install the stopper ring (2).

| Caution make sure that the stopper ring is fitted securely into the groove. |

- Press fit the dust seal (1).

- Insert the spring collar a (7) and spring (8) into the inner tube.

- Insert the spring collar b (9) into the inner tube.

| Caution face the flange “d” of the collar to the spring side. |

|

- Pour specified fork oil until its surface passes the side holes of inner tube.

: Fork oil 99000–99001–ss5

: Fork oil 99000–99001–ss5

(suzuki

fork oil ss-05 or equivalent)

- Slowly stroke the outer tube more than ten times to pump out air.

| Note take extreme attention to pump out air completely. |

- Assemble the piston rod and rod guide case (10).

- Tighten the piston rod nut (11) with the special tool and vise.

Tightening torque piston rod nut (a): 28 n·m (2.8 Kgf-m, 20.0 Lbf-ft)

- Insert the piston rod assembly into the inner tube and temporarily tighten the rod guide case by hand.

| Caution insert the piston rod assembly into the inner tube with the outer tube lifted up. Be sure not to damage the piston ring (12) of the rod guide case. |

Special tool

(b): 09940–84710 (rod guide case

(b): 09940–84710 (rod guide case

wrench)

- Tighten the rod guide case to the specified torque.

Refer to “rod guide case tightening torque” .

Special tool

(b): 09940–84710 (rod guide case

(b): 09940–84710 (rod guide case

wrench)

Tightening torque rod guide case: 90 n·m (9.0 Kgf-m, 65.0 Lbf-ft)

- Pour specified fork oil up to the top of the rod guide case.

: Fork oil

: Fork oil

99000–99001–ss5 (suzuki

fork oil ss-05 or equivalent)

- Push the front fork cap, then stroke the outer tube several times to pump out air.

| Note take extreme attention to pump out the air completely. |

- Hold the front fork vertically and adjust the oil level using the special tool.

Special tool

(c): 09943–74111 (front fork oil

(c): 09943–74111 (front fork oil

level

gauge)

Fork oil level “a” 75.0 Mm (2.95 In)

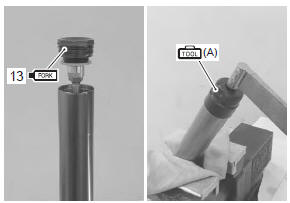

- Apply fork oil to the o-ring (13).

| Caution use new o-ring to prevent oil leakage. |

- Tighten the front fork cap to the specified torque.

| Caution do not clamp the outer tube too tight. |

Tightening torque front fork cap: 35 n·m (3.5 Kgf-m, 25.5 Lbf-ft)

Special tool

(a): 09941–53670 (front fork cap

(a): 09941–53670 (front fork cap

socket

wrench (45 mm))

Front suspension adjustment

Front suspension adjustment

After installing the front fork, adjust the spring pre-load

and two kinds of damping force as follows:

Adjust the

left and right front forks to the

same setting.

Spring pre-load ...

Front fork parts inspection

Front fork parts inspection

Refer to “front fork disassembly and assembly” .

Inner and outer tubes

Inspect the inner tube and outer tube for scratches

Slide bushing / guide bushing

Inspect the slide bushing and guide bus ...

Other materials:

DTC “c21” (p0110-h/l): iat sensor circuit

malfunction

Detected condition and possible cause

Detected condition

Possible cause

C21

Output voltage is not with in the following

range.

0.15 V ≤ Sensor voltage < 4.85 V

Iat sensor circuit open or short.

Iat sensor malfunction.

Ec ...

Specifications

Service data

Fi sensors

Tightening torque specifications

Reference: for the tightening torque of fastener not specified in this

section, refer to “tightening torque list” in section 0c . ...

DTC “c12” (p0335): ckp sensor circuit

malfunction.

Detected condition and possible cause

Detected condition

Possible cause

The signal does not reach ecm for 3 sec. Or more, after

receiving the starter signal.

Metal particles or foreign material being stuck on the

ckp sensor and rotor tip.

Ckp ...