Suzuki GSX-R 1000 Service Manual: Front fork removal and installation

| Note the right and left front forks are installed symmetrically and therefore the removal procedure for one side is the same as that for the other side. |

Removal

- Remove the front wheel. Refer to “front wheel assembly removal and installation” in section 2d .

Caution

|

- Disconnect the brake hoses from the clamps on the front fender.

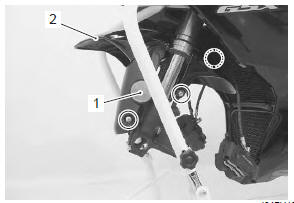

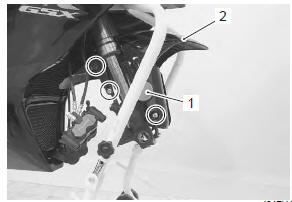

- Remove the reflex reflectors (1). (Except for e-02, 19, 51)

- remove the front fender (2) by removing the bolts

- Loosen the front fork upper clamp bolt (3).

- Loosen the handlebar clamp bolt (4).

| Note slightly loosen the front fork cap (5) to facilitate later disassembly. |

Special tool

: 09941–53670 (front fork cap

: 09941–53670 (front fork cap

socket

wrench (45 mm))

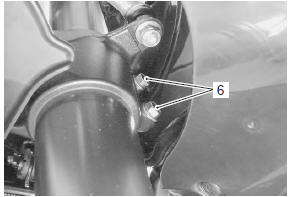

- Loosen the front fork lower clamp bolts (6) and remove the front fork.

| Note hold the front fork by hand to prevent it sliding out of the steering stem. |

Installation

- Set the front fork to the steering stem lower bracket temporarily by tightening the lower clamp bolts (1).

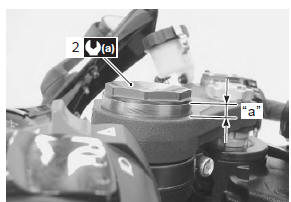

- Tighten the front fork cap (2) to the specified torque.

Tightening torque front fork cap (a): 35 n·m (3.5 Kgf-m, 25.5 Lbf-ft)

- Loosen the lower clamp bolts.

- Set the front fork with the edge of the outer tube positioned 7.0 Mm (0.28 In) “a” from the upper surface of the upper bracket.

|

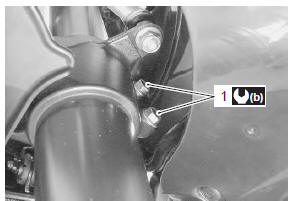

- Tighten the front fork lower clamp bolts (1).

Tightening torque front fork lower clamp bolt (b): 23 n·m (2.3 Kgfm, 16.5 Lbf-ft)

- Tighten the front fork upper clamp bolt (3).

Tightening torque front fork upper clamp bolt (c): 23 n·m (2.3 Kgfm, 16.5 Lbf-ft)

- Tighten the handlebar clamp bolt (4).

Tightening torque handlebar clamp bolt (d): 23 n·m (2.3 Kgf-m, 16.5 Lbf-ft)

- Install the front wheel. Refer to “front wheel assembly removal and installation” in section 2d .

After After

remounting the brake calipers, pump the brake lever until the pistons push the pads correctly. |

| Note before tightening the front axle bolt and front axle pinch bolts, move the front fork up and down four or five times. |

Front fork components

Front fork components

Front fork cap

O-ring

Rebound damping force adjuster rod

Compression damping force adjuster rod

Piston rod nut

O-ring

Piston ring

Rod guide case

Spr ...

Front suspension adjustment

Front suspension adjustment

After installing the front fork, adjust the spring pre-load

and two kinds of damping force as follows:

Adjust the

left and right front forks to the

same setting.

Spring pre-load ...

Other materials:

Camshaft sprocket

Inspect the camshaft sprocket in the following

procedures:

remove the intake and exhaust camshafts. Refer to “engine top side

disassembly” .

Inspect the teeth of each camshaft sprocket for wear

or damage.

If they are worn or damaged, replace the sprocket/

camshaft assembl ...

Rear wheel components

Rear axel nut

Collar

Dust seal

Bearing

Retainer

Rear sprocket

Sprocket mounting drum

Wheel damper

Bearing

Spacer

Air valve

Rear wheel

Wheel balancer

Rear tire

Dust seal

Collar

Rear brake disc

Rear axle

1 ...

Brakes

This motorcycle has front and

rear disk brakes.

Warning

Failure to inspect and properly

maintain the brakes increases

your chance of having an accident.

Inspect the brake system

before each use according to

the inspection before

riding section. Follow the

maintenance ...