Suzuki GSX-R 1000 Service Manual: Open circuit check

Possible causes for the open circuit are as follows. As the cause can exist in the connector/coupler or terminal, they need to be checked carefully.

- Loose connection of connector/coupler.

- Poor contact of terminal (due to dirt, corrosion or rust, poor contact tension, entry of foreign object etc.).

- Wire harness being open.

- Poor terminal-to-wire connection.

When checking system circuits including an electronic control unit such as ecm, etc., It is important to perform careful check, starting with items which are easier to check.

- Disconnect the negative (–) cable from the battery.

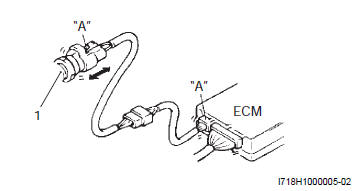

- Check each connector/coupler at both ends of the circuit being checked for loose connection. Also check for condition of the coupler lock if equipped.

|

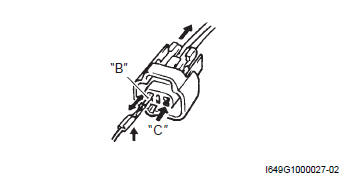

- Using a test male terminal, check the female

terminals of the circuit being checked for contact

tension.

Check each terminal visually for poor contact (possibly caused by dirt, corrosion, rust, entry of foreign object, etc.). At the same time, check to make sure that each terminal is fully inserted in the coupler and locked.

If contact tension is not enough, rectify the contact to increase tension or replace. The terminals must be clean and free of any foreign material which could impede proper terminal contact.

|

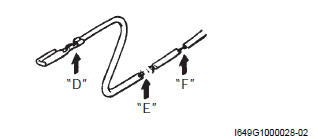

- Using continuity inspect or voltage check procedure

as described below, inspect the wire harness

terminals for open circuit and poor connection.

Locate abnormality, if any.

|

Battery

Battery

Battery connection in reverse polarity is strictly

prohibited. Such a wrong connection will damage the

components of the fi system instantly when reverse

power is applied.

Removing ...

Continuity check

Continuity check

Measure resistance across coupler “b” (between “a”

and “c” in figure).

If no continuity is indicated (infinity or over limit), the

circuit is open between terminals “a” and “c”.

Dis ...

Other materials:

Starter motor will not run

Note

make sure the fuses are not blown and the battery is fully-charged

before diagnosing.

Troubleshooting

Step

Action

Yes

No

1

Shift the transmission into neutral.

Grasp the clutch lever, turn on the ignition switch ...

Battery

Battery connection in reverse polarity is strictly

prohibited. Such a wrong connection will damage the

components of the fi system instantly when reverse

power is applied.

Removing any battery terminal of a running engine is

strictly prohibited. The moment such removal is made,

...

Cam chain tension adjuster inspection

The cam chain tension adjuster is maintained to proper

tension automatically.

Remove the cam chain tension adjuster. Refer to “engine top side

disassembly” .

Holding the cam chain tension adjuster as shown in

the figure, compress the plunger by turning the

adjuster body unt ...