Suzuki GSX-R 1000 Service Manual: Radiator / cooling fan motor removal and installation

Removal

- Remove the inner under cowlings. Refer to “exterior parts removal and installation” in section 9d .

- Drain engine coolant. Refer to “cooling system inspection” in section 0b .

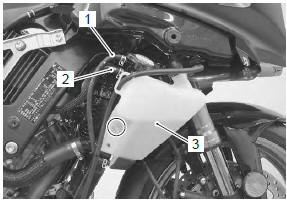

- Disconnect the reservoir tank inlet hose (1) and water air bleed hose (2).

- Remove the radiator reservoir tank (3).

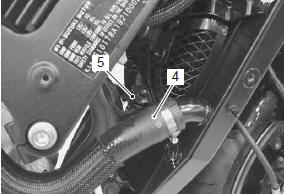

- Disconnect the radiator inlet hose (4).

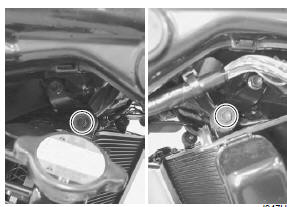

- Disconnect the cooling fan motor coupler (5).

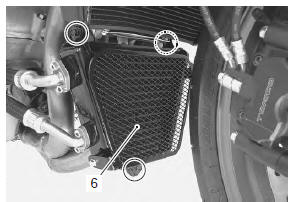

- Remove the oil cooler (6) from the bracket.

- Remove the radiator assembly by removing the bolts.

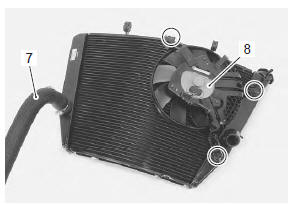

- Remove the radiator outlet hose (7) and cooling fan motor (8) from the radiator.

Installation

Install the radiator in the reverse order of removal. Pay attention to the following points:

- install the radiator and oil cooler to their bracket. Refer to “radiator inspection and cleaning” .

- Apply thread lock to the reservoir tank bolt and tighten it securely.

: Thread lock cement

: Thread lock cement

99000–32110

(thread lock cement super “1322” or

equivalent)

- Connect the radiator hoses securely. Refer to “water hose routing diagram” .

- Pour engine coolant. Refer to “cooling system inspection” in section 0b .

- Bleed air from the cooling circuit. Refer to “cooling system inspection” in section 0b .

Radiator inspection and cleaning

Radiator inspection and cleaning

Radiator hose inspection

Refer to “cooling system inspection” in section 0b .

Radiator inspection

Inspect the radiator for water leaks. If any defects are

found, replace the radiator with a new on ...

Water hose inspection

Water hose inspection

Inspect the water hoses in the following procedures:

remove the side cowlings. Refer to “exterior parts

removal and installation” in section 9d (page 9d-

6).

Check the water hose ...

Other materials:

Oil pressure switch inspection

Inspect the oil pressure switch in the following

procedures:

Note

before inspecting the oil pressure switch, check if the engine oil level

is correct. Refer to “engine oil and filter replacement” in section 0b .

Remove the left side cowling. Refer to “exterior parts removal ...

Water hose removal and installation

Removal

Remove the side cowlings. Refer to “exterior parts

removal and installation” in section 9d (page 9d-

6).

Drain engine coolant. Refer to “cooling system inspection” in section

0b .

Lift and support the fuel tank. Refer to “fuel tank

removal and installation” in se ...

Front brake master cylinder components

Reservoir cap

Plate

Diaphragm

Reservoir tank

Master cylinder

Dust boot

Piston set

Brake lever

Brake lever pivot bolt

Brake lever pivot bolt lock-nut

Brake light switch

Brake hose union bolt

Brake hose

23 N·m (2.3 Kgf-m,

...