Suzuki GSX-R 1000 Service Manual: Side-stand / ignition interlock system parts inspection

Check the interlock system for proper operation. If the interlock system does not operate properly, check each component for damage or abnormalities. If any abnormality is found, replace the component with a new one.

Side-stand switch

- Turn the ignition switch off.

- Remove the left side cowling. Refer to “exterior parts removal and installation” in section 9d .

- Disconnect the side-stand switch coupler (1).

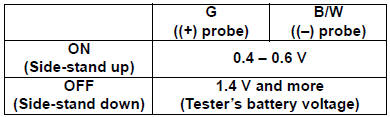

- Measure the voltage between g and b/w lead wires.

Special tool

: 09900–25008 (multi circuit tester

: 09900–25008 (multi circuit tester

set)

Tester knob indication

diode test ( )

)

| Note if the tester reads 1.4 V and below when the tester probes are not connected, replace its battery. |

- Connect the side-stand switch coupler.

- Install the removed parts.

Turn signal / side-stand relay

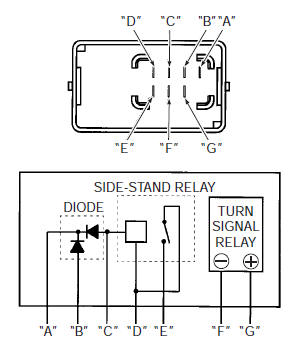

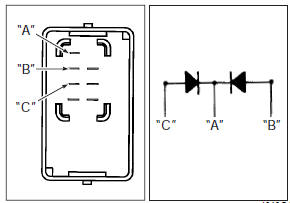

The turn signal/side-stand relay is composed of the turn signal relay, side-stand relay and diode.

Side-stand relay

- Remove the turn signal/side-stand relay. Refer to “turn signal / side-stand relay removal and installation” .

- Check the insulation between “d” and “e” terminals using the multi-circuit tester.

- Apply 12 v to terminals “d” and “c” ((+) to “d” and (– ) to “c”) and check the continuity between “d” and “e”. If there is no continuity, replace the turn signal/ side-stand relay with a new one.

Special tool

: 09900–25008 (multi circuit tester

: 09900–25008 (multi circuit tester

set)

Tester knob indication

continuity test (  )

)

- Install the turn signal/side-stand relay. Refer to “turn signal / side-stand relay removal and installation” .

Diode inspection

- Remove the turn signal/side-stand relay. Refer to “turn signal / side-stand relay removal and installation” .

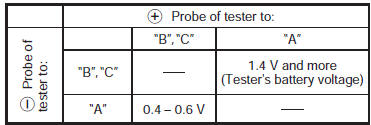

- Measure the voltage between the “a”, “b” and “c” terminals using the multi-circuit tester.

Special tool

: 09900–25008 (multi circuit tester

: 09900–25008 (multi circuit tester

set)

Tester knob indication

diode test (  )

)

| Note if the multi circuit tester reads 1.4 V and below when the tester probes are not connected, replace its battery. |

- Install the turn signal/side-stand relay. Refer to “turn signal / side-stand relay removal and installation” .

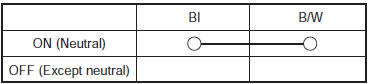

Gear position switch

- Lift and support the fuel tank. Refer to “fuel tank removal and installation” in section 1g (page 1g- 9).

- Disconnect the gear position switch coupler (1).

| Caution when disconnecting and connecting the gear position switch coupler, make sure to turn off the ignition switch, or electronic parts may get damaged. |

- Check the continuity between bl and b lead wires with the transmission in “neutral”.

Special tool

: 09900–25008 (multi circuit tester

: 09900–25008 (multi circuit tester

set)

Tester knob indication

continuity test ( )

)

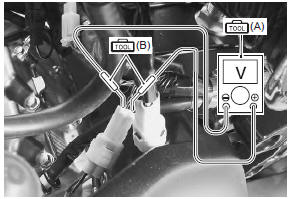

- Connect the gear position switch coupler to the wiring harness.

- Insert the needle pointed probes to the lead wire coupler.

- Turn the ignition switch on and side-stand to upright position.

- Measure the voltage between p and b/w lead wires using the multi-circuit tester when shifting the gearshift lever from low to top.

Special tool

(a): 09900–25008 (multi circuit

(a): 09900–25008 (multi circuit

tester set)

(b): 09900–25009 (needle-point

(b): 09900–25009 (needle-point

probe set)

Tester knob indication

voltage ( )

)

Gear position switch voltage (except neutral position) 0.6 V and more ((+) p – (–) b/w)

- Turn the ignition switch off.

- Install the removed parts.

Turn signal / side-stand relay removal and

installation

Turn signal / side-stand relay removal and

installation

Removal

Turn the ignition switch off.

Remove the frame cover assembly. Refer to “exterior parts removal and

installation” in section 9d .

Remove the turn signal/side-stand relay ...

Starter torque limiter removal and

installation

Starter torque limiter removal and

installation

Removal

Remove the clutch assembly. Refer to “clutch removal” in section 5c .

Remove the washer (1), starter idle gear no. 1 (2)

And starter torque limiter (3).

Installation

Inst ...

Other materials:

Rear shock absorber inspection

Refer to “rear shock absorber removal and installation” .

Shock absorber

Inspect the rear shock absorber for damage and oil

leakage, and absorber bushing for wear and damage. If

any defect is found, replace the rear shock absorber with

a new one.

Caution

do not attempt to disassemble ...

Rear brake hose removal and installation

Removal

Drain brake fluid. Refer to “brake fluid replacement” .

Remove the rear brake hoses as shown in the rear brake hose routing

diagram. Refer to “rear brake hose routing diagram” .

Installation

Caution

the seal washers should be replaced with

new ones to prevent ...

Drive chain cleaning and

oiling

Clean and oil the chain as follows:

Wash the chain with kerosene.

Kerosene will lubricate and

clean the chain.

Warning

Kerosene can be hazardous .

Kerosene is flammable. Children

or pets may be harmed

from contact with kerosene.

Keep flames and smoking

mater ...