Suzuki GSX-R 1000 Service Manual: Starter motor inspection

Refer to “starter motor disassembly and assembly” .

Carbon brush

Inspect the carbon brushes for abnormal wear, cracks or smoothness in the brush holder.

If either carbon brush is defective, replace the brush holder set with a new one.

Measure the length “a” of the carbon brushes using a vernier calipers. If the measurement is less than the service limit, replace the housing end assembly (outside) with a new one.

Brush length “a” service limit: 3.5 Mm (0.14 In)

Special tool

: 09900–20102 (vernier calipers

: 09900–20102 (vernier calipers

(200 mm))

Commutator

Inspect the commutator for discoloration, abnormal wear or undercut “a”.

If the commutator is abnormally worn, replace the armature assembly.

If the commutator surface is discolored, polish it with #400 sandpaper and wipe it using a clean, dry cloth.

If there is no undercut, scrape out the insulator (1) with a saw blade.

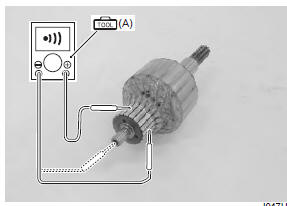

Armature coil

Inspect for continuity between each segment.

Inspect for continuity between each segment and the armature shaft.

If there is no continuity between the segments or there is continuity between the segments and shaft, replace the armature assembly with a new one.

Special tool

(a): 09900–25008 (multi circuit

(a): 09900–25008 (multi circuit

tester set)

Tester knob indication

continuity set (  )

)

Bearing

Check the bearings for damage.

If any damage is found, replace the housing end.

Oil seal

Check the seal lip for damage.

If any damage is found, replace the housing end.

Starter motor disassembly and assembly

Starter motor disassembly and assembly

Refer to “starter motor removal and installation” .

Disassembly

Disassemble the starter motor as shown in the starter motor components

diagram. Refer to “starter motor components” .

Assembly

Rea ...

Starter relay removal and installation

Starter relay removal and installation

Removal

Turn the ignition switch off.

Remove the front seat. Refer to “exterior parts

removal and installation” in section 9d (page 9d-

6).

Disconnect the battery (–) lead wire ...

Other materials:

Gearshift lever construction

Gearshift lever bracket

Gearshift lever shaft

Washer

Snap ring

Gearshift lever

Footrest top surface

65 – 75 Mm (2.6 – 3.0 In)

28 N·m (2.8 Kgf-m,

20.0 Lbf-ft)

40 N·m

(4.0 Kgf-m, 29.0 Lbf-ft)

Apply grease.

Grease.

...

Drive chain related parts inspection

Refer to “rear sprocket / rear sprocket mounting drum removal and

installation” .

Dust seal

Inspect the dust seal for wear or damage. If any damage

is found, replace the dust seal with a new one.

Bearing

Inspect the play of the sprocket mounting drum bearing

by hand while it is in the dr ...

Engine assembly installation

Install the engine in the reverse order of engine removal.

Pay attention to the following points:

before installing the engine, install the collars (1).

Before installing the engine, install the engine

mounting thrust adjusters (2).

Gradually raise the rear side of ...