Suzuki GSX-R 1000 Service Manual: Crankshaft journal bearing inspection and selection

Refer to “engine bottom side disassembly” (page 1d- 49).

Refer to “engine bottom side assembly” .

Inspection

- Inspect each upper and lower crankcase bearing for any damage.

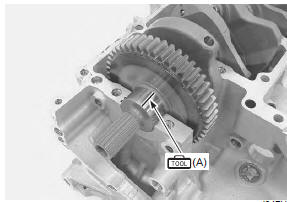

- Set the crankshaft onto the upper crank case.

- Install the plastigauge onto each crankshaft journal.

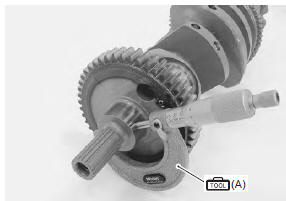

Special tool

(a): 09900–22301 (plastigage (0.025 –

(a): 09900–22301 (plastigage (0.025 –

0.076

Mm))

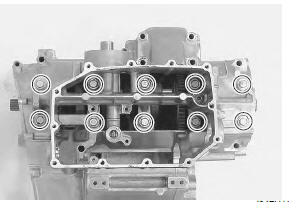

- Mate the lower crankcase with the upper crankcase.

- Tighten the crankshaft journal bolts (m9). Tighten each bolt a little at a time to equalize the pressure in the following two steps.

| Note do not rotate the crankshaft when a piece of plastigauge is installed. |

Tightening torque crankshaft journal bolt (m9): 18 n·m (1.8 Kgf-m, 13.0 Lbf-ft) then turn in 50°

- Remove the lower crankcase and measure the width of compressed plastigauge using the envelope scale. This measurement should be taken at the widest part of the compressed plastigauge. If the oil clearance exceeds the service limit, select the specified bearings from the bearing selection table.

Crankshaft journal oil clearance standard: 0.016 – 0.034 Mm (0.0006 – 0.0013 In)

Crankshaft journal oil clearance service limit: 0.080 Mm (0.0031 In)

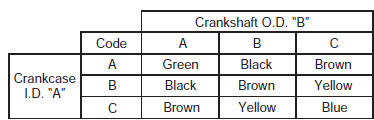

Selection

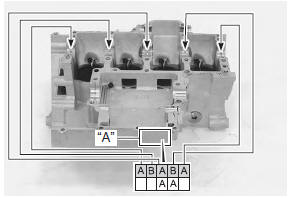

- Check the corresponding crankcase journal i.D.

Codes “a” ([a], [b] or [c]), which are stamped on the rear of the upper crankcase.

Crankcase journal i.D. Specification

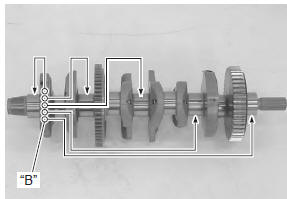

- Check the corresponding crankshaft journal o.D.

Codes “b” ([a], [b] or [c]), which are stamped on the crankshaft.

- Measure the crankshaft o.D. With the special tool. If any of the measurements are out of specification, replace the crankshaft.

Crankshaft journal o.D. Specification

Special tool

(a): 09900–20202 (micrometer (25 –

(a): 09900–20202 (micrometer (25 –

50

mm))

- Select the specified bearings from the bearing selection table

Bearing selection table

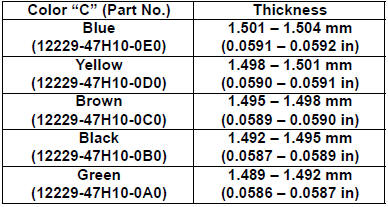

Bearing thickness specification

|

Conrod crank pin bearing inspection and

selection

Conrod crank pin bearing inspection and

selection

Refer to “engine bottom side disassembly” (page 1d-

49).

Refer to “engine bottom side assembly” .

Inspection

Inspect the bearing surfaces for any signs of fusion,

pitting, burn or flaws. If ...

Crankshaft thrust clearance inspection and

selection

Crankshaft thrust clearance inspection and

selection

Refer to “engine bottom side disassembly” (page 1d-

49).

Refer to “engine bottom side assembly” .

Inspection

With the crankshaft’s right-side and left-side thrust

bearings inserted into the ...

Other materials:

Conrod and crankshaft inspection

Refer to “engine bottom side disassembly” (page 1d-

49).

Refer to “engine bottom side assembly” .

Conrod small end I.D.

Measure the conrod small end inside diameter using the

small bore gauge.

If the conrod small end inside diameter exceeds the

service limit, replace the conrod.

Special ...

Drive chain related components

Drive chain

Engine sprocket

Rear sprocket

Dust seal

Bearing

Retainer

Sprocket mounting drum

Wheel damper

145 N·m (14.5 Kgf-m,

105.0 Lbf-ft)

60 N·m

(6.0 Kgf-m, 43.0 Lbf-ft)

Apply grease

Apply thread lock to

thread p ...

Front turn signal light removal and installation

Removal

Remove the screw.

Disconnect the front turn signal coupler (1).

Remove the turn signal light assembly (2).

Installation

Install the front turn signal light in the reverse order of

removal. ...