Suzuki GSX-R 1000 Service Manual: Conrod and crankshaft inspection

Refer to “engine bottom side disassembly” (page 1d- 49).

Refer to “engine bottom side assembly” .

Conrod small end I.D.

Measure the conrod small end inside diameter using the small bore gauge.

If the conrod small end inside diameter exceeds the service limit, replace the conrod.

Special tool

(a): 09900–20602 (dial gauge)

(a): 09900–20602 (dial gauge)

(b): 09900–22401 (small bore gauge

(b): 09900–22401 (small bore gauge

(10 – 18

mm))

Conrod small end i.D.

Service limit: 15.040 Mm (0.5921 In)

Conrod big end side clearance

- Check the conrod big end side clearance using the thickness gauge.

Special tool

(a): 09900–20803 (thickness gauge)

(a): 09900–20803 (thickness gauge)

Conrod big end side clearance service limit: 0.30 Mm (0.012 In)

- If the clearance exceeds the limit, remove the conrod and measure the conrod big end width and crank pin width. Refer to “engine bottom side assembly” . If any of the measurements are out of specification, replace the conrod or crankshaft.

Special tool

(b): 09900–20205 (micrometer (0 –

(b): 09900–20205 (micrometer (0 –

25 mm))

(c): 09900–20605 (dial calipers (10

(c): 09900–20605 (dial calipers (10

– 34

mm))

Conrod big end width standard: 19.95 – 20.00 Mm (0.7854 – 0.7874 In)

Crank pin width standard: 20.10 – 20.15 Mm (0.7913 – 0.7933 In)

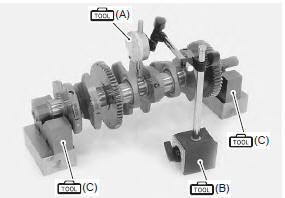

Crankshaft runout

Support the crankshaft using v-blocks as shown, with the two end journals resting on the blocks. Set up the dial gauge as shown, and rotate the crankshaft slowly to read the runout. Replace the crankshaft if the runout exceeds the service limit.

Special tool

(a): 09900–20607 (dial gauge)

(a): 09900–20607 (dial gauge)

(b): 09900–20701 (dial gauge chuck)

(b): 09900–20701 (dial gauge chuck)

(c): 09900–21304 (v blocks)

(c): 09900–21304 (v blocks)

Crankshaft runout service limit: 0.05 Mm (0.002 In)

Conrod crank pin bearing removal and

installation

Conrod crank pin bearing removal and

installation

Refer to “engine bottom side disassembly” (page 1d-

49).

Refer to “engine bottom side assembly” .

Removal

Remove the conrod crank pin bearings (1).

Note

do not remove the beari ...

Conrod crank pin bearing inspection and

selection

Conrod crank pin bearing inspection and

selection

Refer to “engine bottom side disassembly” (page 1d-

49).

Refer to “engine bottom side assembly” .

Inspection

Inspect the bearing surfaces for any signs of fusion,

pitting, burn or flaws. If ...

Other materials:

Iat sensor removal and installation

Removal

Remove the air cleaner box. Refer to “air cleaner box removal and

installation” in section 1d .

Remove the iat sensor (1) from the air cleaner box.

Installation

Install the iat sensor in the reverse order of removal.

Pay attention to the following point:

t ...

Rear brake pedal removal and installation

Removal

Remove the master cylinder assembly. Refer to “rear brake master

cylinder assembly removal and installation” .

Disconnect the rear brake light switch lead wire coupler. Refer to

“rear brake light switch inspection” .

Remove the rear brake pedal as shown in the rear ...

Front brake light switch inspection

Inspect the front brake light switch in the following

procedures:

disconnect the front brake light switch coupler (1).

Inspect the front brake light switch for continuity with

the tester.

If any abnormality is found, replace the front brake light switch with a new

one. Re ...