Suzuki GSX-R 1000 Service Manual: Crankshaft thrust clearance inspection and selection

Refer to “engine bottom side disassembly” (page 1d- 49).

Refer to “engine bottom side assembly” .

Inspection

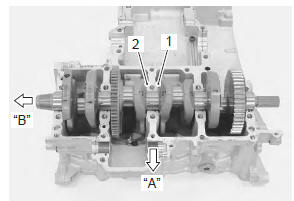

- With the crankshaft’s right-side and left-side thrust bearings inserted into the upper crankcase.

- Measure the thrust clearance “a” between the leftside thrust bearing and crankshaft using the thickness gauge. If the thrust clearance exceeds the standard range, adjust the thrust clearance.

| Note pull the crankshaft to the left (generator side) so that there is no clearance on the right-side thrust bearing. |

Special tool

: 09900–20803 (thickness gauge)

: 09900–20803 (thickness gauge)

Crankshaft thrust clearance “a” standard: 0.060 – 0.110 Mm (0.0024 – 0.0043 In)

|

Selection

- Remove the right-side thrust bearing and measure its thickness using the micrometer. If the thickness of the right-side thrust bearing is below standard, replace it with a new bearing and measure the thrust clearance again, as described in inspection 1) and 2).

Special tool

(a): 09900–20205 (micrometer (0 – 25

(a): 09900–20205 (micrometer (0 – 25

mm))

Right-side thrust bearing thickness standard: 2.420 – 2.440 Mm (0.0953 – 0.0961 In)

- If the right-side thrust bearing is within the standard range, reinsert the right-side thrust bearing and remove the left-side thrust bearing.

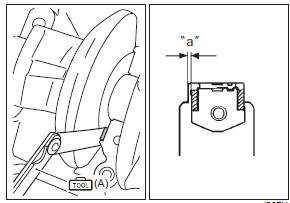

- With the left-side thrust bearing removed, measure the clearance “a” using the thickness gauge as shown.

Special tool

(b): 09900–20803 (thickness gauge)

(b): 09900–20803 (thickness gauge)

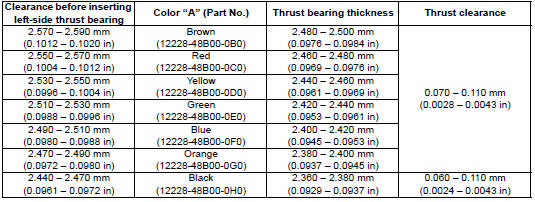

- Select a left-side thrust bearing from the selection table.

| Note right-side thrust bearing has the same specification as the green (12228-48b00-0e0) of left-side thrust bearing. |

Thrust bearing selection table

|

- After selecting a left-side thrust bearing, install it and then measure the thrust clearance again.

Crankshaft journal bearing inspection and

selection

Crankshaft journal bearing inspection and

selection

Refer to “engine bottom side disassembly” (page 1d-

49).

Refer to “engine bottom side assembly” .

Inspection

Inspect each upper and lower crankcase bearing for

any damage.

Set ...

Specifications

Specifications

...

Other materials:

Cooling fan relay inspection

Inspect the fan relay in the following procedures:

remove the frame covers. Refer to “exterior parts

removal and installation” in section 9d (page 9d-

6).

Remove the cooling fan relay (1).

First check the insulation between “a” and “b”

terminals with tester. Then ap ...

Swingarm related parts inspection

Refer to “swingarm removal and installation” (page 2c-

9).

Spacers

Remove the collar and spacer from the swingarm.

Inspect the collars and spacer for wear and damage.

If any defects are found, replace them with new

ones.

Chain buffer

Inspect the chain buffer for wear and ...

License plate light bulb replacement

Caution

when you touch the bulb with your bare

hands, clean the bulb with a cloth moistened

with alcohol or soap water to prevent

premature bulb failure.

Remove the license plate light mounting nuts.

Remove the lens cover (1) by removing the screws.

Re ...