Suzuki GSX-R 1000 Service Manual: Self-diagnosis function

The self-diagnosis function is incorporated in the ecm. The function has two modes, “user mode” and “dealer mode”.

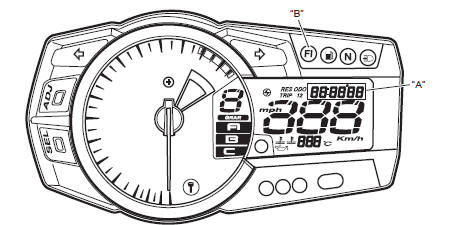

The user can only be notified by the lcd (display) panel and led (fi indicator light). To check the function of the individual fi system devices, the dealer mode is provided. In this check, the special tool is necessary to read the code of the malfunction items.

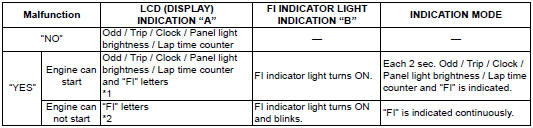

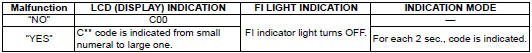

User mode

*1

When one of the signals is not received by ecm, the fail-safe circuit works and injection is not stopped. In this case, “fi” and odd / trip / clock / panel light brightness / lap time counter are indicated in the lcd panel and motorcycle can run.

*2

The injection signal is stopped, when the camshaft position sensor signal, crankshaft position sensor signal, tip-over sensor signal, #1, #2, #3 and #4 ignition signals, #1, #2, #3 and #4 injector signals, fuel pump relay signal or ignition switch signal is not sent to ecm. In this case, “fi” is indicated in the lcd panel. Motorcycle does not run.

“Chec”:

the lcd panel indicates “chec” when no communication signal from the ecm is received for 5 seconds.

For example:

the ignition switch is turned on, and the engine stop switch is turned off. In this case, the speedometer does not receive any signal from ecm, and the panel indicates “chec”. If chec is indicated, the lcd does not indicate the trouble code. It is necessary to check the wiring harness between ecm and speedometer couplers.The possible cause of this indication is as follows: engine stop switch is in off position. Side-stand/ignition inter-lock system is not working. Ignition fuse is burnt.

“Sd”:

the lcd panel indicates “sd” when the steering damper solenoid malfunction, battery abnormal voltage and speed sensor malfunction occurred.

Dealer mode

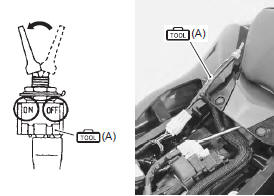

The defective function is memorized in the computer. Use the special tool’s coupler to connect to the mode select switch. The memorized malfunction code is displayed on lcd (display) panel. Malfunction means that the ecm does not receive signal from the devices. These affected devices are indicated in the code form.

Caution Caution

If the coupler from the ecm is disconnected, the malfunction code memory is erased and the malfunction code can not be checked. |

Special tool

(a): 09930–82720 (mode selection

(a): 09930–82720 (mode selection

switch)

Injection timing description

Injection timing description

Injection time (injection volume)

The factors to determine the injection time include the basic fuel injection

time, which is calculated on the basis of the

intake air pressure, engine speed and t ...

Schematic and routing diagram

Schematic and routing diagram

FI system wiring diagram

Terminal alignment of ecm coupler

...

Other materials:

Specifications

Service data

Injector + fuel pump + fuel pressure regulator

Fuel

Tightening torque specifications

Note

the specified tightening torque is described in the following.

“Fuel pump components”

Reference: for the tightening torque of fastener not specified in this

se ...

Fuel pump relay inspection

Refer to “electrical components location” in section 0a .

Inspect the fuel pump relay in the following procedures:

remove the frame covers. Refer to “exterior parts

removal and installation” in section 9d (page 9d-

6).

Remove the fuel pump relay (1).

First, check f ...

Engine assembly installation

Install the engine in the reverse order of engine removal.

Pay attention to the following points:

before installing the engine, install the collars (1).

Before installing the engine, install the engine

mounting thrust adjusters (2).

Gradually raise the rear side of ...