Suzuki GSX-R 1000 Service Manual: Fuel pump disassembly and assembly

Disassembly

- Remove the fuel tank. Refer to “fuel tank removal and installation” .

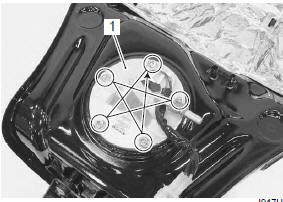

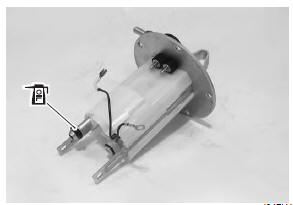

- Remove the fuel pump assembly (1) by removing its mounting bolts diagonally.

|

|

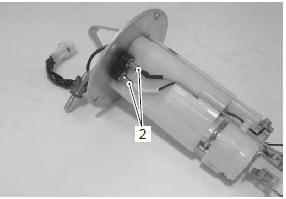

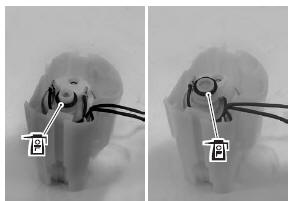

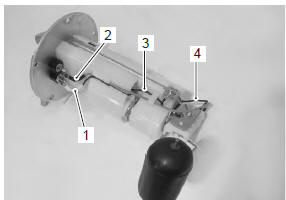

- Disconnect the lead wires (2).

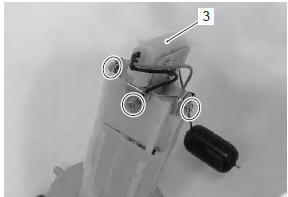

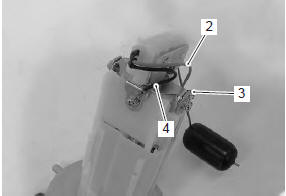

- Remove the fuel level gauge (3).

- Remove the fuel pressure regulator assembly (4).

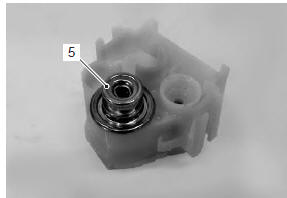

| Caution never remove the fuel pressure regulator (5) from the holder. |

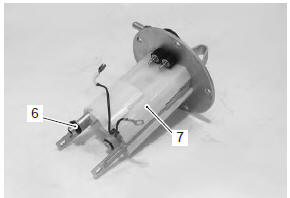

- Remove the o-ring (6) and fuel pump case (7).

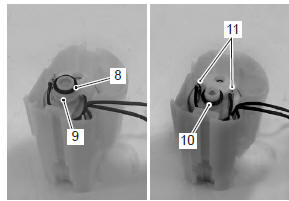

- Remove the o-ring (8) and joint (9).

- Remove the o-ring (10) and lead wires (11).

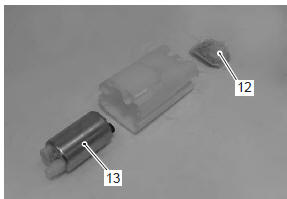

- Remove the fuel mesh filter (12).

- Remove the fuel pump (13).

Assembly

Refer to “fuel mesh filter inspection and cleaning” .

Assemble the fuel tank pump in the reverse order of the disassembly. Pay attention to the following points:

Caution

|

| Caution connect all lead wires securely so as not to cause contact failure. |

|

- Install a new o-ring and apply grease to it.

: Grease 99000–25010 (suzuki

: Grease 99000–25010 (suzuki

super

grease “a” or equivalent)

The o-ring The o-ring

must be replaced with a new one to prevent fuel leakage. |

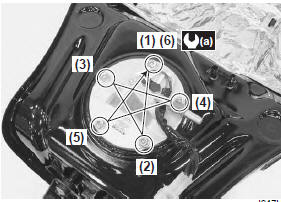

- When installing the fuel pump assembly, first tighten all the fuel pump mounting bolts lightly and then to the specified torque in the ascending of numbers.

Tightening torque fuel pump mounting bolt (a): 10 n·m (1.0 Kgf-m, 7.0 Lbf-ft)

Fuel pump components

Fuel pump components

Fuel level gauge

Fuel pressure regulator assembly

O-ring

Joint

Fuel pump

Fuel pump case

Fuel mesh filter

10

N·m (1.0 Kgf-m, 7.0 Lbf-ft)

Appl ...

Fuel mesh filter inspection and cleaning

Fuel mesh filter inspection and cleaning

Inspect the fuel mesh filter in the following procedures:

remove the fuel mesh filter. Refer to “fuel pump disassembly and

assembly” .

If the fuel mesh filter is clogged with fore ...

Other materials:

Wheel / tire / air valve inspection and cleaning

Refer to “tire removal and installation” .

Wheel

Wipe the wheel clean and check for the following points:

distortion and crack

any flaws and scratches at the bead seating area.

Wheel rim runout. Refer to “front wheel related parts inspection”

and “rear wheel rela ...

Precautions

Precautions for wheel and tire

Proper tire pressure and proper tire loading are important

factors. Over loading tire can lead to tire

failure and loss of motorcycle control.

Under-inflated tires make smooth cornering difficult, and

can result in rapid tire wear.

...

Cushion lever removal and installation

Removal

Remove the right side cowling and side frame covers. Refer to “exterior

parts removal and installation” in section 9d .

Support the motorcycle with a jack to relieve load on

the cushion levers.

Remove the left muffler and muffler chamber heat guard no. 2. Refer to

...