Suzuki GSX-R 1000 Service Manual: Fuel pump relay inspection

Refer to “electrical components location” in section 0a .

Inspect the fuel pump relay in the following procedures:

- remove the frame covers. Refer to “exterior parts removal and installation” in section 9d (page 9d- 6).

- Remove the fuel pump relay (1).

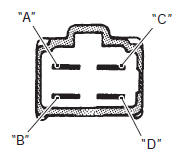

- First, check for insulation with the tester between terminals “a” and “b”. Next, check for continuity between “a” and “b” with 12 v voltage applied, positive (+) to terminal “c” and negative (–) to terminal “d”. If continuity does not exist, replace the relay with a new one.

Special tool

: 09900–25008 (multi circuit tester

: 09900–25008 (multi circuit tester

set)

Tester knob indication

continuity test (  )

)

Fuel hose inspection

Refer to “fuel line inspection” in section 0b (page 0b- 10).

Fuel level gauge inspection

Refer to “fuel level gauge inspection” in section 9c .

Fuel discharge amount inspection

Fuel discharge amount inspection

Keep away from fire or spark.

Spilled gasoline should be wiped off

immediately.

Work in a well-ventilated area.

Inspect the fuel discharge amo ...

Fuel tank construction

Fuel tank construction

Fuel tank heat

shield

: aluminum film side should face the engine side.

Fuel tank front cover

Fuel tank front bracket

Velcro fastenings

: clean the adhesiv ...

Other materials:

Gearshift shaft / gearshift cam plate components

Gearshift shaft

Gearshift cam drive plate

Gearshift cam plate

Gearshift cam stopper

19 N·m (1.9 Kgf-m,

13.5 Lbf-ft)

13 N·m

(1.3 Kgf-m, 9.5 Lbf-ft)

8.5 N·m

(0.85 Kgf-m, 6.0 Lbf-ft)

Apply grease to oil

seal lip.

Apply thread l ...

Fuel tank removal and installation

Removal

Keep away from fire or spark.

Spilled gasoline should be wiped off

immediately.

Work in a well-ventilated area.

Remove the front seat. Refer to “exterior parts

removal and installation” in section 9d (page 9d-

6).

Take ...

Light bulb replacement

The wattage rating of each bulb is

shown in the following chart.

When replacing a burned-out

bulb, always use the same wattage

rating according to the following

chart.

Caution

Using a light bulb with the

wrong wattage rating can

cause electrical system damage

or shorte ...