Suzuki GSX-R 1000 Service Manual: Swingarm removal and installation

Removal

- Cut the drive chain. Refer to “drive chain replacement” in section 3a .

- Remove the rear wheel assembly. Refer to “rear wheel assembly removal and installation” in section 2d .

- Disconnect the rear brake hose from the brake hose clamp (1).

- Remove the brake hose clamp bolt (2).

- Remove the rear brake caliper from the swingarm.

- Remove the left muffler and muffler chamber heat guard no. 2. Refer to “muffler / muffler chamber / exhaust pipe removal and installation” in section 1k .

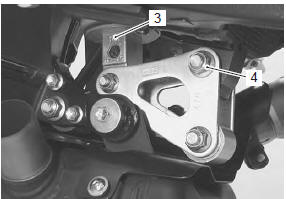

- Remove the rear shock absorber (3) and cushion lever mounting bolt and nut (4). Refer to “rear shock absorber removal and installation” and “cushion lever removal and installation” .

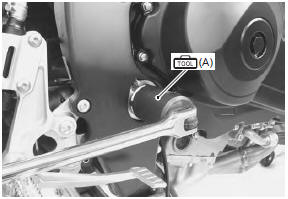

- Remove the swingarm pivot shaft lock-nut with the special tool.

Special tool

(a): 09940–14940 (swingarm pivot

(a): 09940–14940 (swingarm pivot

thrust

adjuster wrench)

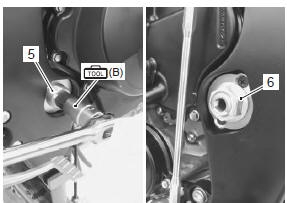

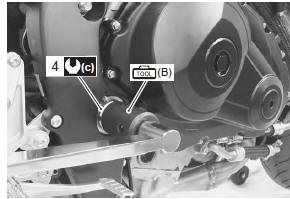

- Hold the swingarm pivot shaft (5) with the special tool and remove the swingarm pivot nut (6).

Special tool

(b): 09944–28321 (hexagon socket

(b): 09944–28321 (hexagon socket

(19

mm))

- Remove the swingarm pivot shaft.

- Remove the swingarm assembly.

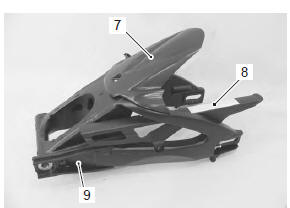

- Remove the mudguard (7), chain case (8) and chain buffer (9) from the swingarm.

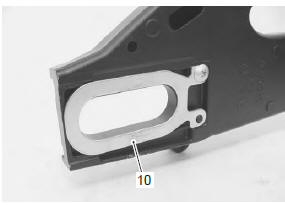

- Remove the plate (10).

Installation

Install the swingarm in the reverse order of removal. Pay attention to the following points:

- install the plate.

| Note when reusing the removed screw (1), apply a small quantity of the thread lock to it. |

: Thread lock cement

: Thread lock cement

99000–32110

(thread lock cement super “1322” or

equivalent)

- Adjust swingarm pivot thrust clearance in the following procedures:

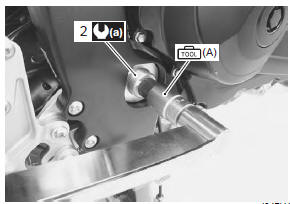

– insert the swingarm pivot shaft (2) and tighten it to the specified torque with the special tool.

Special tool

(a): 09944–28321 (hexagon socket

(a): 09944–28321 (hexagon socket

(19

mm))

Tightening torque swingarm pivot shaft (a): 15 n·m (1.5 Kgf-m, 11.0 Lbf-ft)

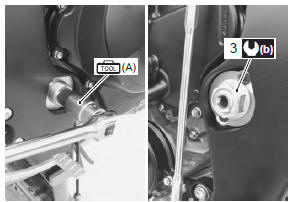

– Hold the swingarm pivot shaft with the special tool and tighten the swingarm pivot nut (3) to the specified torque.

Special tool

(a): 09944–28321 (hexagon socket

(a): 09944–28321 (hexagon socket

(19

mm))

Tightening torque swingarm pivot nut (b): 100 n·m (10.0 Kgf-m, 72.5 Lbf-ft)

– Tighten the swingarm pivot lock-nut (4) to the specified torque with the special tool.

Special tool

(b): 09940–14940 (swingarm pivot

(b): 09940–14940 (swingarm pivot

thrust

adjuster wrench)

Tightening torque swingarm pivot lock-nut (c): 90 n·m (9.0 Kgfm, 65.0 Lbf-ft)

- Tighten the cushion lever, cushion rod and rear shock absorber mounting bolts and nuts to the specified torque.

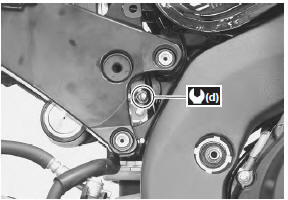

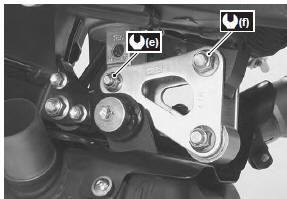

Tightening torque rear shock absorber upper mounting nut (d): 50 n·m (5.0 Kgf-m, 36.0 Lbf-ft) rear shock absorber lower mounting nut (e): 50 n·m (5.0 Kgf-m, 36.0 Lbf-ft) cushion lever mounting nut (f): 98 n·m (9.8 Kgfm, 71.0 Lbf-ft)

Cushion rod bearing removal and installation

Cushion rod bearing removal and installation

Removal

Remove the cushion rod. Refer to “cushion rod removal and installation”

.

Remove the cushion rod bearing with the special

tool.

Special tool

(a):

09921–20240 (bearing re ...

Swingarm pivot boss removal and installation

Swingarm pivot boss removal and installation

Removal

Remove the swingarm. Refer to “swingarm removal and installation” .

Remove the swingarm pivot boss nut (1).

Note

remove the swingarm pivot boss only when

replacing ...

Other materials:

Hazard switch inspection

Inspect the hazard switch in the following procedures:

remove the air cleaner box. Refer to “air cleaner box removal and

installation” in section 1d .

Disconnect the left handlebar switch coupler (1).

(Yellow)

Inspect the hazard switch for continuity with the

tes ...

Battery charging

Initial charging

filling electrolyte

Note

when filling electrolyte, the battery must be

removed from the vehicle and must be put on

the level ground.

Remove the aluminum tape (1) which seals the

battery filler holes “a”.

Remove the caps (2) from the electrolyte ...

DTC “c49” (p1656): pair control solenoid

valve circuit malfunction

Detected condition and possible cause

Detected condition

Possible cause

Pair control solenoid valve voltage is not input to ecm

Pair control solenoid valve circuit open or short.

Pair control solenoid valve malfunction.

Ecm malfunction.

...