Suzuki GSX-R 1000 Service Manual: Transmission installation

Install the transmission in the reverse order of removal.

Pay attention to the following points:

Bearing and oil seal

| Caution replace the removed bearings and oil seals with new ones. |

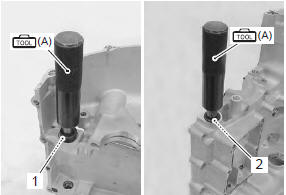

- Install the driveshaft left bearing oil seal into the retainer using the special tool.

Special tool

(a): 09913–70210 (bearing

(a): 09913–70210 (bearing

installing set (10

– 75 Ô))

- Install the driveshaft left bearing with the special tool.

| Note the stamped mark side of the driveshaft left bearing faces outside. |

Special tool

(a):

09913–70210 (bearing installing set (10

– 75Ôö))

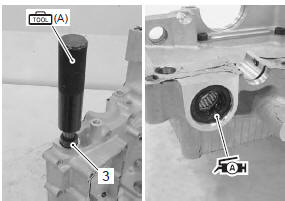

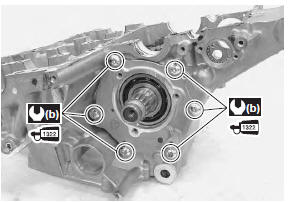

- Install the gearshift shaft bearings (1) and (2) with the special tool.

| Note the stamped mark side of the gearshift shaft bearing faces outside. |

Special tool

(a): 09913–70210 (bearing

(a): 09913–70210 (bearing

installing set (10

– 75 Ô))

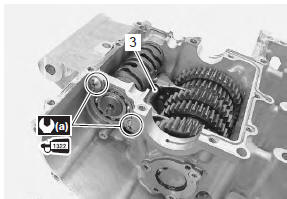

- Install the gearshift shaft oil seal (3) with the special tool.

Special tool

(a): 09913–70210 (bearing

(a): 09913–70210 (bearing

installing set (10

– 75 Ô))

- Apply grease to the oil seal lip.

: Grease 99000–25010 (suzuki

: Grease 99000–25010 (suzuki

super

grease “a” or equivalent)

- Install the gearshift cam bearing with the special tool.

Special tool

(a): 09913–70210 (bearing

(a): 09913–70210 (bearing

installing set (10

– 75 Ô))

Driveshaft assembly

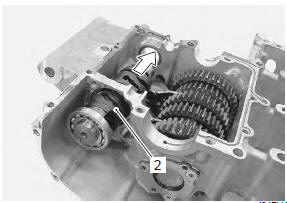

- Put the driveshaft assembly (1) into the lower crankcase.

- Install the driveshaft right bearing assembly (2).

- Apply thread lock to the bolts and tighten them to the specified torque.

: Thread lock cement

: Thread lock cement

99000–32110

(thread lock cement super “1322” or

equivalent)

Tightening torque driveshaft right bearing case bolt (a): 12 n·m (1.2 Kgf-m, 8.7 Lbf-ft)

- Install the dowel pin.

- Apply grease to the o-ring and install the driveshaft left bearing case (3).

| Caution replace the o-ring with a new one. |

: Grease 99000–25010 (suzuki

: Grease 99000–25010 (suzuki

super

grease “a” or equivalent)

- Apply thread lock to the bolts and tighten them to the specified torque.

: Thread lock cement

: Thread lock cement

99000–32110

(thread lock cement super “1322” or

equivalent)

Tightening torque driveshaft left bearing case bolt (b): 12 n·m (1.2 Kgf-m, 8.7 Lbf-ft)

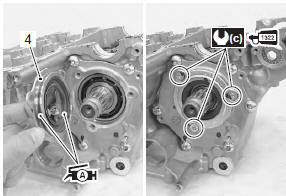

- Apply grease to the oil seal lip and o-ring.

| Caution replace the o-ring with a new one. |

: Grease 99000–25010 (suzuki

: Grease 99000–25010 (suzuki

super

grease “a” or equivalent)

- Install the oil seal retainer (4).

- Apply thread lock to the screws and tighten them to the specified torque.

: Thread lock cement

: Thread lock cement

99000–32110

(thread lock cement super “1322” or

equivalent)

Tightening torque driveshaft oil seal retainer screw (c): 12 n·m (1.2 Kgf-m, 8.7 Lbf-ft)

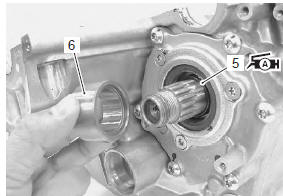

- Apply grease to the o-ring (5) and install it to the driveshaft.

| Caution replace the o-ring with a new one. |

: Grease 99000–25010 (suzuki

: Grease 99000–25010 (suzuki

super

grease “a” or equivalent)

- Install the spacer (6).

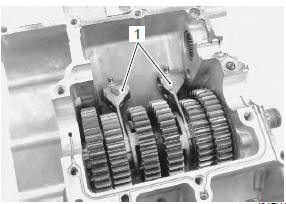

Gearshift cam and gearshift fork

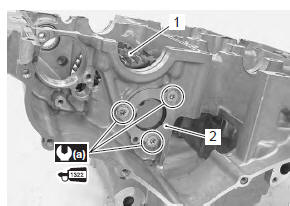

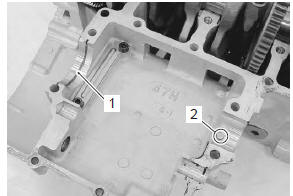

- Install the gearshift forks (1) as shown.

- Install the gearshift cam (2) with the bearing fitted.

- With engaging each fork end to the cam groove, insert the fork shaft (3).

- Apply thread lock to the screws and tighten them to the specified torque.

: Thread lock cement

: Thread lock cement

99000–32110

(thread lock cement super “1322” or

equivalent)

Tightening torque gearshift cam bearing retainer screw (a): 10 n·m ( 1.0 Kgf-m, 7.0 Lbf-ft)

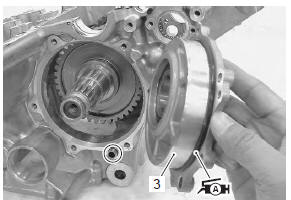

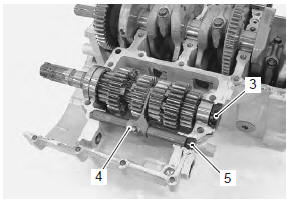

Countershaft

- Install the c-ring (1) and bearing pin (2) to the upper crankcase.

- Install the countershaft assembly to the upper crankcase.

| Note align the c-ring with the groove of bearing and the bearing pin with the indent on the bearing. |

- Turn the bearing and set the bearing dowel pin in position.

- Install the clutch push rod oil seal (3).

- Install the gearshift fork/gearshift shaft (4) and gearshift shaft plug (5).

Transmission removal

Transmission removal

Remove the engine assembly from the frame. Refer to “engine assembly

removal” in section 1d .

Remove the engine top side. Refer to “engine top side disassembly” in

section 1d .

&nbs ...

Transmission construction

Transmission construction

Countershaft

Driveshaft

...

Other materials:

Ecm removal and installation

Removal

Remove the frame covers. Refer to “exterior parts

removal and installation” in section 9d (page 9d-

6).

Disconnect the battery (–) lead wire.

Remove the tool set (1) and prop stay (2).

Disconnect the hose clamp (3) (e-33 only) and

starter relay (4).

Remo ...

Crankshaft thrust clearance inspection and

selection

Refer to “engine bottom side disassembly” (page 1d-

49).

Refer to “engine bottom side assembly” .

Inspection

With the crankshaft’s right-side and left-side thrust

bearings inserted into the upper crankcase.

Measure the thrust clearance “a” between the leftside

thrust bearing and ...

Tightening torque list

Engine

Fi system + intake air system

Cooling system

Chassis

Tightening torque chart

For other bolts and nuts not listed in the preceding page, refer to this

chart:

Conventional bolt

“4” Marked bolt

“7” Marked bolt

...